How NATPAT Built a Wellness Patch Empire

Imagine being on holiday in Paris, working late at night, when your phone lights up with a notification. You glance at the screen and see that Kim Kardashian just posted about your product to her 329 million Instagram followers.

Your first thought: fake account.

Your second thought, after checking: this is real.

That’s exactly what happened to Michael Jankie, co-founder of NATPAT, when the reality star bought BuzzPatch mosquito repellent stickers and shared them on Instagram in September 2022. The company didn’t pay her for the endorsement or send her free products. They had no idea she was even a customer.

“When Kim Kardashian bought BuzzPatch and posted about it, we had no idea until it happened,” Michael recalls. “Suddenly sales spiked, our phones lit up, and people started seeing us as credible.”

Today, NATPAT has sold more than 1.5 million packs of wellness stickers across its product line. The company’s revenues are “well into eight figures” across direct-to-consumer, marketplace, and wholesale channels. Their products are available at Target, Walmart, Amazon, Woolworths, iHerb and in markets across Australia, North America, Europe, the UK, and Singapore.

But NATPAT didn’t start with aspirations of celebrity endorsements or eight-figure revenues. It started in Michael Jankie’s backyard in Australia, watching his kids play and feeling frustrated every time he reached for the chemical spray bottle.

This is the story of how two friends built a wellness patch business on problems they faced as parents. And it’s also the story of how an unexpected Instagram post from one of the world’s most famous women validated everything they’d been building.

When Spraying Your Kids Doesn’t Feel Right

“The idea started in my own backyard in Australia, watching my kids play and realizing how often we were spraying chemicals on them,” Michael explains. “It didn’t feel right. I wanted something safe, simple, and fun that my children would actually enjoy using.”

That frustration—that nagging discomfort every parent feels when doing something they’re not entirely comfortable with—turned into curiosity. And curiosity turned into a question: what if there was a better way?

“That frustration turned into curiosity, and from there the sticker idea was born,” Michael says.

The logic was simple. Kids love stickers. They’ll wear them voluntarily, happily, without complaint. So why not make stickers that do something functional while being fun?

Michael Jankie, Gary Tramer, and Andrei Safonau founded NATPAT (Natural Patch Co.) in April 2020, drawing on their wealth of experience in eCommerce and startups. The timing couldn’t have been worse—or perhaps, in retrospect, better. The pandemic had just begun. Supply chains were chaotic. Consumer behavior was unpredictable.

But families stuck at home were spending more time outdoors in their yards and local parks. Mosquito season was coming. And parents were increasingly conscious about what chemicals they put on their children’s skin.

The first BuzzPatch packs were sold in May 2020, just one month after founding. The stickers used natural essential oils—particularly citronella—infused into colorful, kid-friendly patches that could be stuck on clothing rather than applied directly to skin.

No DEET. No harsh chemicals. Just plant-based essential oils that mosquitoes happened to hate, delivered in a format kids wanted to wear.

Building Trust Over Decades

The NATPAT founding story has an unusual element that most startups can’t replicate: Michael Jankie and Gary Tramer have been friends since they were three years old.

“That kind of history builds deep trust,” Michael says.

Think about what that means for a business partnership. It means no need to prove motives and no uncertainty about whether your co-founder will prioritize personal gain over the company’s mission. No awkward early conversations trying to align on values because the values are already aligned after decades of friendship.

“When we started NATPAT, the focus was never on money first,” Michael explains. “It was about creating something safe for our kids. That foundation of honesty and care is what shaped our culture from day one.”

This wasn’t abstract philosophy. It shaped concrete decisions.

“This philosophy shows up in practical ways,” Michael says. “We design for safety first, we keep the company flexible and family-friendly, and we say no to opportunities that don’t align with our values even if they look profitable.”

That last part—saying no to profitable opportunities—is where most businesses reveal whether their stated values are real or just marketing copy. NATPAT takes the hard step of turning down revenue when it would compromise what they’ve built.

“Profit matters, but joy is what makes the business sustainable,” Michael notes.

The Australian roots also matter. The products are formulated and designed in Australia, bringing a specific approach to natural wellness that resonates with parents globally. The company draws on indigenous communities’ centuries-old use of essential oils for insect repellent, combining traditional knowledge with modern delivery mechanisms.

Reaching 329 Million Followers with Zero Warning

Even though their products received high praise and generated expected revenue, the legitimacy of NATPAT as a business was a constant question mark.

Were sales driven by marketing or genuine product quality? Were they building something real or just riding a temporary trend? As inventors and owners, they constantly wondered if the product was actually good enough.

Then came September 2022.

“When Kim Kardashian bought BuzzPatch and posted about it, we had no idea until it happened,” Michael says. He was on holiday in Paris, working at night as entrepreneurs do, when the notification came through. His immediate reaction was skepticism—probably a fake account using Kim’s name.

But it wasn’t fake. Kim Kardashian had genuinely purchased BuzzPatch (the team still doesn’t know from where—their website, a retailer, or Amazon), used it, and decided to share it with her 329 million Instagram followers in an Instagram story.

“Suddenly sales spiked, our phones lit up, and people started seeing us as credible,” Michael recalls.

The NATPAT team quickly assembled online from different parts of the globe to strategize. But the right response was obvious: lean into the moment while staying authentic to what they’d built.

“It was less about celebrity validation and more about realizing the idea had crossed into the mainstream,” Michael explains. “That gave us the confidence to double down.”

The deeper significance wasn’t just the sales spike. It was the answer to that nagging question about product quality versus marketing.

She didn’t receive free product. She wasn’t paid for the endorsement. She bought BuzzPatch because she needed mosquito repellent for her kids, it worked, and she chose to share it.

That organic endorsement—from someone who could have anything for free—validated that NATPAT had built something genuinely good.

The experience also shaped NATPAT’s current marketing approach. While the company has experimented with influencer marketing, they now focus primarily on resharing genuine posts from customers.

Creating Products Around Their Own Problems

How does NATPAT decide which products to develop? The answer reveals why their product line resonates so strongly with parents.

“Every product comes from a problem in our own homes,” Michael explains. “Sleep, focus, allergies—these were not opportunities we spotted in a market report, they were real needs we faced as parents.”

Start with BuzzPatch, the original mosquito repellent sticker. The essential oil blend—citronella combined with other natural oils—creates what NATPAT describes as a “virtual shield” that confuses mosquitoes and hides children from their senses.

Because mosquitoes find humans by sensing the carbon dioxide we exhale, certain essential oils can overpower that CO2 signal, essentially making you invisible to mosquitoes.

But BuzzPatch was just the beginning. Once the technology proved effective, Michael and Gary looked at other problems they faced as parents.

For sleep troubles, they created SleepyPatch with essential oils like mandarin, lavender, sweet marjoram, and vetiver designed to calm the nervous system and promote relaxation.

Focus and concentration issues, they made FocusPatch for school, homework, sports, and activities.

For big emotions and anxiety, they launched ZenPatch for mood calming and emotional regulation.

For congestion from colds or allergies, they introduced StuffyPatch for respiratory relief.

The product development process is consistent: “We look for natural solutions, test them thoroughly, and only bring them to life if our own kids would use them,” Michael says.

The technology behind all NATPAT products is AromaWeave™, a bamboo-based fiber using nanomaterial that releases essential oil molecules consistently—approximately every 30 seconds—rather than dissipating quickly after opening the package. This allows the patches to work for 8-12 hours depending on the product.

The patches are made with medical-grade non-woven fabric and adhesive safe enough for children’s clothing but strong enough to stay put during active play. The colorful emoji face stickers make them fun for kids to choose and wear.

The parent appeal is equally important: stick them on clothing rather than applying chemicals directly to skin, no messy sprays or creams, DEET-free and plant-based, and kids are more likely to want to wear them.

Making Value-Driven Decisions

Most companies claim to be values-driven. NATPAT’s approach reveals the difference between values as marketing and values as operating principles.

“This philosophy shows up in practical ways,” Michael explains. “We design for safety first, we keep the company flexible and family-friendly, and we say no to opportunities that don’t align with our values even if they look profitable.”

Designing for safety first means using only natural ingredients, testing formulations thoroughly, choosing medical-grade materials, and avoiding harsh chemicals like DEET or synthetic compounds. Every product must pass the test: would Michael and Gary use this on their own children?

Keeping the company family-friendly means understanding that parents work around children’s schedules. It means building flexibility into company culture rather than demanding traditional office hours and presence. It means recognizing that sometimes business decisions need to wait until after bedtime.

Saying no to profitable opportunities is the hardest part. When a partnership or distribution channel offers significant revenue but requires compromising on ingredients, messaging, or brand values, NATPAT walks away.

“Profit matters, but joy is what makes the business sustainable,” Michael emphasizes.

Instead of scaling according to conventional wisdom—raising venture capital, expanding rapidly, maximizing short-term revenue—NATPAT chose to maintain the fun and passion in their work. They collaborate with like-minded partners who share their values rather than pursuing every available opportunity.

Michael credits his support system for enabling this approach: friends, colleagues, other startup founders, and even retired founders who now invest. They provide advice, brainstorm ideas, and think constructively about the business. That community gives NATPAT the confidence to stay true to their mission even when conventional business logic suggests different choices.

Making a Real Difference

Revenue numbers and celebrity endorsements tell one story about NATPAT’s success. But Michael measures success differently.

“A parent once told us their child with autism could not focus in school until they tried our Focus Patch,” Michael shares. “That story hit me hard.”

The realization was profound: “It showed me that what we are building is not just about mosquito bites or sleep, but about genuinely helping families. Those stories are what keep us moving forward.”

The customer testimonials reveal the breadth of impact NATPAT products have on real families:

A mother wrote about her newborn son who loves evening walks: “We have not had a single bug bite since we started using these stickers. The fact that it is chemical-free was a huge selling point for me.”

A parent shared about their daughter with autism: “I needed help for my autistic daughter to get some sleep at night.” After using SleepyPatch: success.

An adult customer wrote: “I can climb into bed, fall asleep, stay asleep (that’s new!) and waken refreshed about 7-8 hours later! I haven’t slept this well in around 20 years!!”

A stay-at-home mom described her high-energy child: “I decided to give these a try. I was so surprised that he actually was calm and played with blocks for over two hours and I got to finally have a break!”

One customer even used ZenPatch for a stressed cat exhibiting behavioral issues: “I thought we’d give these patches a try” and the calming effect worked for the pet.

These aren’t just product reviews. They’re stories about quality of life improvements for families struggling with real challenges.

What Comes Next

From a backyard in Australia to 1.5 million packs sold. From launching during a pandemic to revenues “well into eight figures.” From unknown brand to organic endorsement by Kim Kardashian.

The NATPAT journey demonstrates what happens when founders build products they genuinely need for their own families. When childhood friendships create business partnerships rooted in deep trust. When values drive decisions even at the cost of short-term profits.

Michael and Gary didn’t set out to build a wellness empire. They set out to stop spraying chemicals on their kids. The sticker idea that emerged from that frustration solved a real problem in a format children actually enjoyed.

Then they applied the same problem-first approach to sleep, focus, mood, congestion, and allergies. Every product comes from a problem they faced in their own homes. Every product gets tested on their own kids first.

The accidental celebrity endorsement validated what they’d built, but it didn’t change the fundamental approach. NATPAT still focuses on resharing genuine customer stories rather than paying influencers. They still say no to opportunities that compromise their values. They still measure success by impact on families’ lives rather than just revenue growth.

The lesson for other entrepreneurs isn’t about getting lucky with celebrity attention. It’s about building something so genuinely good that when someone with 329 million followers discovers it organically, they choose to share it without payment or incentive.

You can explore NATPAT’s full product line at natpat.com including BuzzPatch, SleepyPatch, and Wellness Kits.

Key Takeaways

Did you read this piece looking for tips on how to grow your own business? Here are some things that stood out to me.

Build what you’d use yourself.

Every NATPAT product solves a problem Michael and Gary faced with their own kids. When founders are the target customer, product-market fit comes naturally. So make products you’d feel comfortable using yourself.

Organic advocacy beats paid influencers.

Kim Kardashian bought and posted without payment or free product. Now NATPAT focuses on resharing genuine customer posts. Authentic testimonials “are the ones that work and resonate” more than sponsored content.

Problem-first beats market-first.

Sleep, focus, allergies—”not opportunities we spotted in a market report, they were real needs we faced as parents.” Market research identifies gaps but lived experience identifies solutions people truly desire.

Values-driven means saying no to profits (sometimes).

“We say no to opportunities that don’t align with our values even if they look profitable.” Turning down revenue that compromises principles is what makes the difference between value-washing and value-driven.

Launch timing matters less than product quality.

Founded April 2020 during pandemic, first sales May 2020. Terrible timing became irrelevant when the product solved a genuine problem.

Joy makes business sustainable, not just profitable.

“Profit matters, but joy is what makes the business sustainable.” Maintaining fun and passion while scaling preserves founder motivation and company culture long-term.

Imagine managing fresh-roasted coffee in grocery aisles and supplying independent restaurants and cafes, while also doing private labeling and custom blending, providing business coaching to aspiring cafe owners, AND expanding into 20 new retail locations.

That’s a lot to handle. Especially when you’re doing it as coffee prices hit record highs and new tariffs get slapped on imports.

That’s the reality for Klatch Coffee, the Rancho Cucamonga-based family roaster that’s been building direct relationships with coffee producers for 30 years.

Founded in 1993 by Mike Perry and his wife Cindy, Klatch Coffee has grown from weekly coffee dates to a multi-channel operation. And it’s a big one that includes standalone cafes, wholesale partnerships, direct-to-consumer eCommerce, and now a major expansion into Sprouts Farmers Market stores.

Today, CEO Heather Perry (a 2-time US Barista Champion) and Director of Retail Holly Goldsworthy run the family business. Justin Christopher, Manager of Ecommerce and Marketing, helps orchestrate the myriad factors that going into keeping quality high across every channel.

As Justin says, “we’re all on board with building an interest and appreciation for high-quality specialty coffee. Everyone’s success is our success, because our primary goal is to spread joy one cup of great coffee at a time!”

This is the story of how a family-owned coffee roaster handles the major operation that has grown through the cumulative changes that happen over 30+ years of business. Much of this is thanks to the relationships Klatch Coffee has built up over the years, and that’s a theme we’ll explore in detail in this entrepreneur feature.

Wholesale, DTC, Private Label, and Everything In Between

Let’s start with the obvious question: how does Klatch Coffee manage so many different channels?

“We’re fortunate to have some great wholesale partnerships,” Justin says. “Those partnerships take place in a few different forms. We have fresh-roasted coffee in the grocery aisle at retail partners, we supply organizations like independent restaurants, cafes, and churches, and we offer private or white labeling and even custom blending.”

Some partnerships look completely different. “Finally, we also have partners like UC Riverside, who operate their own businesses, but serve Klatch-inspired beverages and display ‘We proudly brew Klatch Coffee’ signage,” Justin explains.

“We also use our knowledge and expertise to help business owners with menu development, equipment selection, and training at our State-of-the-Art training lab,” Justin notes. “Someone interested in opening their own cafe can reach out to Klatch Coffee for business coaching to help them be successful.”

The result is “a lot of different channels and customers, in addition to direct to consumer sales!”

Now it’s not too hard to imagine how you can slowly add channels to a functional business over the decades, one at a time, like repainting the walls of an old home. But with multiple channels can come complexity (or if you prefer, chaos). So how do they do all this without the channels competing with one another?

“Internally, we work to make sure our departments like sourcing, production, and marketing are supporting all the channels we ultimately sell in,” Justin explains. In other words, they don’t let information silos build up between wholesale, retail, and DTC.

When Coffee Prices Hit Historic Highs

Expanding across channels is challenging when coffee prices hit record highs.

“The state of the world coffee market is fairly challenging currently,” Justin explains. “Prices paid by importers and roasters reached new record highs in early 2025, retracted slightly over the Summer, and remain at historical highs as we enter October.”

Then it got worse. “This was all before new tariffs were added on imports to the United States, too,” Justin notes. “Add new tariffs on some key countries (such as Brazil—the world’s largest coffee producer), and you have a recipe for price increases on the grocery shelf or in your favorite cafe.”

So this begs the question: how does Klatch maintain quality without pricing themselves out?

Three decades of relationship building.

“Our Roastmaster and Founder, Mike Perry, plays a critical role in keeping quality high,” Justin says. “Over Klatch Coffee’s 30 year history, he’s developed personal relationships with some of the world’s best producers—many that go back decades.”

Those relationships are a tremendous strategic advantage for the company. “Since we know those producers so well, we have a big head start in choosing coffees that meet our quality standards,” Justin explains.

Keeping Coffee Quality High

Price is one factor, but it’s far from the only factor. Quality is arguably more important, and Klatch sets a high bar. “We only select coffees that score 90 points or above to ensure quality,” says Justin.

It’s here again that Klatch’s existing relationships—and commitment to building new relationships—makes a big difference. “To keep quality high, we’re constantly evaluating coffees, producers, and even entirely new countries of origin to see if they make sense to add to our selection.”

The Direct Trade model makes this sustainable during price spikes. “Additionally, we purchase coffee with a Direct Trade model—we work directly with farmers and producers, cutting out the traditional middle man and allowing us to pay at least 25% above market minimums to ensure our partners are also making livable wages!” Justin explains.

This is supply chain strategy: “Keeping the whole supply chain sustainable and supported is a big part of what we do,” Justin notes.

One important subset of quality, of course, is consistency. Many popular products are blends from multiple origins, which can make keeping quality consistent more than a little tricky.

“Some of our most popular offerings are blends that contain coffee from multiple origins,” Justin says. “Because coffee harvests vary from year to year, the ‘recipe’ for those blends must constantly be monitored and adjusted, so that the flavor is consistent and familiar to the coffee drinker—even when the harvest varies due to climate, temperature, rainfall, soil conditions, etc.”

Delivering consistency when raw materials vary requires serious quality control. “Our QC team and roasting team works hard in this area to deliver these types of results,” Justin explains.

Holiday Coffees & Small Lots

Coffee might seem year-round, but keeping customers engaged requires seasonal thinking.

“As we head into the holidays as of the time of this writing, I’m reminded that we’re launching our 2025 holiday coffees and gift boxes on October 16!” Justin says. “Coffee makes a wonderful gift, and it’s perfect for sharing with friends and family, creating memorable conversations over a cup.”

Special occasion coffees keep things fresh. “We love celebrating a specific holiday or occasion with a special coffee that exists only for a short time—Mother’s Day, Christmas, and so on,” Justin notes. “That helps keep it fresh and interesting for the daily coffee drinker or visitors who come to our cafes multiple times every week.”

It’s here that direct trade creates another advantage: access to coffees larger roasters overlook.

“Because of our direct trade relationships with producers, we’re able to buy in smaller lots, and that means getting access to special coffees that would be overlooked by larger roasters,” Justin says. “Sometimes we only have a few weeks supply, which helps keep things fresh for enthusiasts—there’s always something new to try!”

Club Subscriptions & Recurring Revenue

Subscriptions form a major part of eCommerce strategy. “Subscriptions are also a big part of our eCommerce business,” Justin notes.

Klatch offers two models: standard repeat and Club subscriptions.

“We do offer the ability to subscribe to and receive the same coffee over and over (and many customers do that), but where we really shine is our Club subscriptions,” Justin explains. “Subscribers receive a new selection each month, expertly curated by our team.”

The Club subscriptions serve educational purposes. “This option is great for expanding your knowledge and appreciation of specialty coffee,” Justin says. “Club shipments can introduce subscribers to a new processing method they would not have otherwise experimented with, which keeps things interesting.”

Klatch provides guidance: “Our monthly Club selections also include a postcard with a brewing guide so customers can quickly get the best results without having to experiment,” Justin notes.

The curation is family-driven: Mike Perry curates Single Origin Club, Heather Perry curates Espresso Club, Holly Goldsworthy curates Blends Club.

This also gives Klatch Coffee an opportunity to present its suppliers in the best light too. “We like to ensure that we tell the full story when presenting a new coffee online,” Justin explains. “What’s the back story of the producer? Where was it grown? What’s the climate like? How were the beans processed?”

Breaking Into Sprouts Farmers Market

The biggest recent news is Klatch’s partnership expansion with Sprouts.

“In conjunction with National Coffee Day, we just announced our expansion into 20 new locations inside Sprouts Farmers Market stores across Southern California,” Justin says. “We have 9 new cafes coming in the next 2 quarters, then 11 more in 2026, including our first in San Diego County.”

This expansion will more than double Klatch’s current cafe footprint.

“There’s a close alignment of values between Klatch Coffee and Sprouts Farmers Market—we support one another in our goals,” Justin explains.

The geographic strategy makes sense. “Our partners are all over California, while our cafe business is focused on SoCal—so those partners help us reach customers that aren’t near enough to visit our own cafes,” Justin notes.

The partnership mindset: “They’re partners, not competitors!” Justin emphasizes. “We’re still winning when new customers discover Klatch via social media, online search, or consumer review sites, regardless of where they ultimately end up enjoying Klatch Coffee.”

The omnichannel approach is deliberate. “We win in the marketplace when consumers discover Klatch Coffee, no matter what channel they prefer to shop in,” Justin says. “We want to be part of the conversation regardless of where they make their buying decision.”

What Metrics Does Klatch Coffee Track?

With their big omnichannel approach, you might wonder where Klatch Coffee looks to understand how their business is doing.

“Website sessions are a good leading indicator that will predict our sales in the near future,” Justin explains. “Traffic is higher when we have a compelling selection of new coffees, offers that reward consumer loyalty, and newsworthy events to share with our base.”

Traffic without conversion doesn’t pay bills. “Ecommerce conversion rate is a measure of how effective we are at communicating our messages to those visitors,” Justin says.

Subscriber metrics get special attention. “We’ve also invested heavily in our subscription business over the last year, so we carefully watch the subscriber metrics to make sure the coffees we are selecting are resonating, the delivery experience is timely, and we’re delivering a great value to subscribers,” Justin explains.

Agility and Expertise vs. Scale

How does a family-owned roaster compete with Starbucks?

“As a smaller, more agile competitor I think we have some key advantages to play up compared with national chains,” Justin says.

The first advantage was touched on earlier but is worth reiterating. There’s expertise at the top. CEO Heather Perry is a 2x US barista champion, and “is heavily engaged in menu design and development, tweaking, testing, perfecting until something new is ready for the public,” Justin explains.

“Controlling the entire supply chain from sourcing, roasting, packaging, and distribution is [another advantage],” Justin notes. This makes sense especially when you consider the deep relationships that Klatch Coffee has built over the years.

Scale creates constraints smaller roasters don’t face. “Massive national chains simply can’t manage individual relationships with small, niche coffee producers around the world—but roasters like Klatch Coffee are agile enough to still have personal relationships with those producers, experiment with the roast until it’s perfect, and distribute the fresh-roasted coffee in small batches,” Justin explains.

Klatch’s size is a feature, not limitation.

Changing With the Times

When asked what surprises him, Justin pointed out that “the pace of change is always shocking,” he says. “Whether it’s technical changes like needing to update to a new subscription platform or making sure your website works on the latest mobile devices, things happen fast.”

The future comes faster than expected. “Soon it will be shopping with AI agents or within large language models—perhaps in the future, ChatGPT will discuss your coffee preferences with you and recommend the perfect beans from Klatch Coffee!” Justin notes.

His attitude is one of forward-looking optimization, with him saying “I love the challenge of adapting to whatever the market develops.”

What’s Next for Klatch Coffee

From weekly coffee dates in 1993 to 30+ cafes in 2025. From Rancho Cucamonga to wholesale partnerships across California. From standalone cafes to 20 new Sprouts locations.

Klatch Coffee proves family-owned specialty roasters can compete with national chains through agility, expertise, and direct relationships rather than scale.

Managing wholesale, DTC, private labeling, custom blending, business coaching, and retail locations across sourcing, production, and marketing is—unquestionably—a lot.

But 30 years of relationship building is what makes it work, as does a serious commitment to the highest of quality.

Explore Klatch Coffee at klatchcoffee.com or find locations at their grocery and cafe partners locator.

Key Takeaways

Did you read this piece looking for tips on how to grow your own business? Here are some things that stood out to me.

Multi-channel works best when partners all share a common mission.

Klatch manages wholesale, DTC, private label, and retail without channel conflict. “Externally, they’re partnerships, not competitors.” When everyone builds appreciation for specialty coffee, collaboration beats competition.

Long-term business relationships enable quality during chaos.

Record prices and tariffs squeeze margins. Klatch’s advantage: “Over Klatch Coffee’s 30 year history, he’s developed personal relationships with some of the world’s best producers—many that go back decades.” Relationships built during good times pay off during crises.

Direct Trade requires paying above minimums.

“We work directly with farmers and producers, cutting out the traditional middle man and allowing us to pay at least 25% above market minimums to ensure our partners are also making livable wages!” Sustainable supply chains cost more but provide reliability.

Small-batch agility beats chain scale.

“Massive national chains simply can’t manage individual relationships with small, niche coffee producers around the world—but roasters like Klatch Coffee are agile enough to still have personal relationships with those producers, experiment with the roast until it’s perfect, and distribute the fresh-roasted coffee in small batches.”

Expertise at the top makes it easier to differentiate on quality.

“CEO Heather Perry is a 2x US barista champion, and is heavily engaged in menu design and development, tweaking, testing, perfecting until something new is ready for the public. That type of experience isn’t easily duplicated by a competitor.”

Website sessions predict sales better than vanity metrics.

“Website sessions are a good leading indicator that will predict our sales in the near future. Traffic is higher when we have a compelling selection of new coffees, offers that reward consumer loyalty, and newsworthy events to share with our base.”

Let’s say you’re a new mom, guardian to your teenage sister, and Hurricane Helene just destroyed your home in Tampa. And all this happened only a few years after a car accident that left you in the ICU.

Most people would not choose that moment to build a business.

Whitney Dueñas Richardson did it anyway.

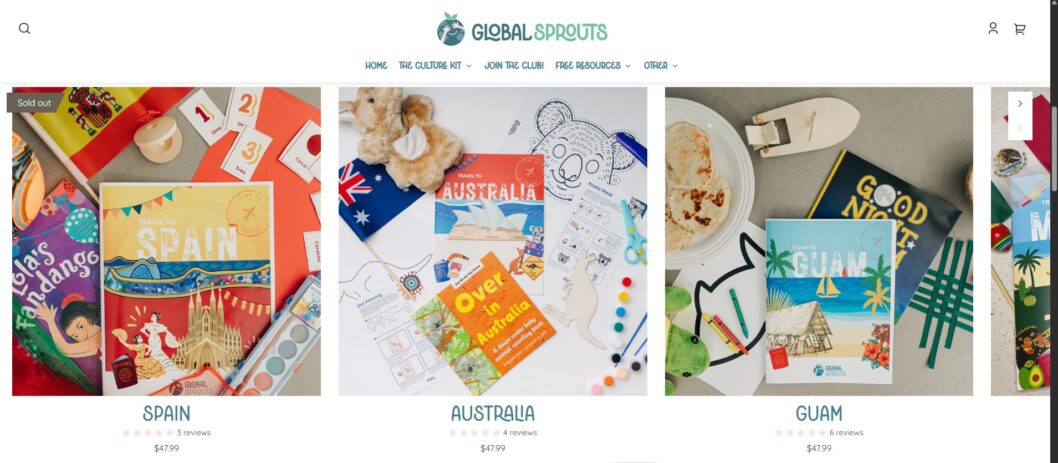

Today, Global Sprouts ships cultural education subscription boxes to families across the United States. At $39.99 per month, each box introduces children ages 2-6 to a different country through hands-on crafts, stories, language learning, and recipes. The boxes are created in partnership with Cultural Ambassadors from each featured country, ensuring authenticity that competitors can’t replicate by Googling.

But Global Sprouts didn’t start in a warehouse or with venture capital. It started at Whitney’s kitchen table, born from a simple realization: she couldn’t find educational materials to teach her daughter about her CHamoru heritage from Guam.

This is the story of how adversity, cultural identity, and corporate marketing experience all came together in the form of a subscription box business.

An Island Most Americans Didn’t Know Exists

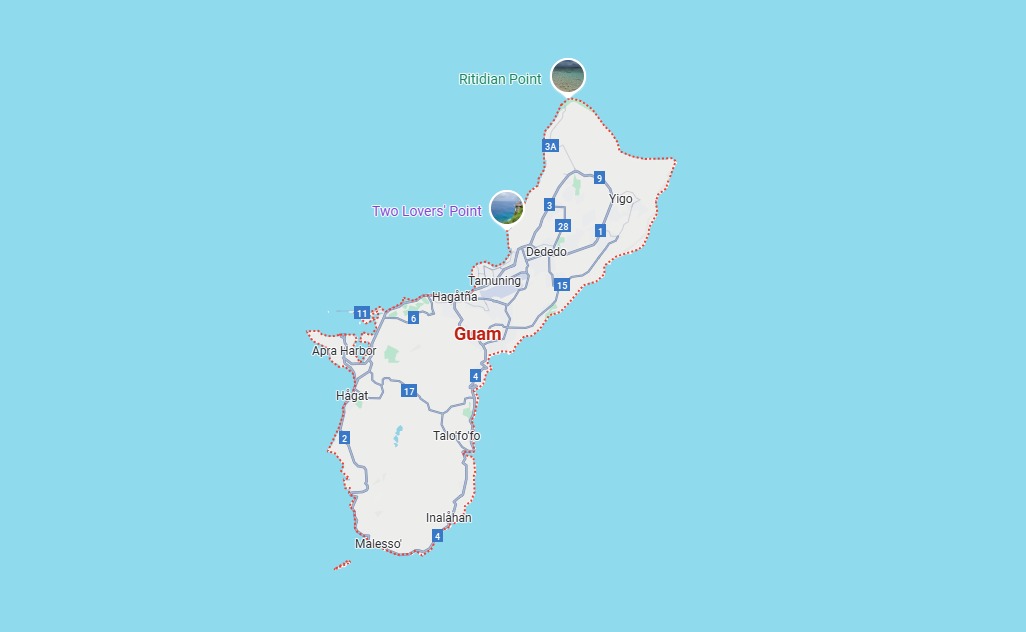

Whitney’s journey to entrepreneurship begins with geography—specifically, an island in the western Pacific that most Americans have never heard of.

“I am from the island of Guam, part Dutch, and moved to the States in 2013, where very few people knew what or where Guam was,” Whitney explains. “I quickly became ‘Whit from Guam’ because people were fascinated by this island they didn’t know existed.”

That fascination would become foundational to her business years later. But first came the realization that sparked everything.

“When I had my daughter two years ago, I found that very few educational resources taught about my culture,” she says. “As I was scrambling to put together cultural activities for her to learn about her heritage, I realized that there had to be other moms out there like me. Moms who want to teach their child about the world but can’t find resources that teach about the people and children of other countries.”

The gap in the market was obvious once Whitney started looking. Plenty of educational materials existed for teaching ABCs and 123s. STEM boxes were everywhere.

But authentic, age-appropriate materials for teaching young children about global cultures? Almost nothing. Just…crickets.

“Global Sprouts was born at my kitchen table because I want parents, grandparents, and caretakers to have access to materials to raise the next generation to be empathetic and accepting of other cultures,” Whitney says.

The personal motivation ran deeper than a business opportunity. Whitney wanted her daughter to grow up knowing all three parts of her identity.

“When I worked in corporate marketing, I loved the creativity and strategy, but after having my daughter, it shifted,” she explains. “I wanted her to grow up knowing who she is, CHamoru, Dutch, and American, and to love that about herself from the very beginning.”

From Marketer to Founder

Before Global Sprouts, Whitney spent years in corporate marketing at Ferguson Enterprises, a major distributor of plumbing supplies and building materials. That experience would prove essential for how she built her subscription box business.

“My marketing experience at Ferguson taught me to dominate local markets first, then follow the breadcrumbs,” Whitney says. “We started in Tampa, expanded into major Texas cities, and plan to grow from larger markets into smaller ones as we scale.”

But the more valuable lesson from Ferguson wasn’t about geography. Rather, it was about who to sell to first.

“It’s actually very similar,” Whitney explains when comparing Ferguson’s B2B approach to Global Sprouts’ strategy. “At Ferguson, our focus was on building relationships with businesses first, contractors, builders, designers, so when homeowners needed products, they already trusted and asked for us by name. With Global Sprouts, we take that same ‘community first’ approach by connecting with schools, teachers, and educational programs. When children experience our kits in the classroom, they go home excited to share them with their parents. In both cases, it’s about building credibility and trust with the community that influences the end consumer. Paid media simply amplifies what we’ve already built through real connections.”

This B2B2C approach—selling to businesses who then influence consumers—is sophisticated for a subscription box startup. But Whitney’s corporate background gave her the playbook.

The transition from corporate marketing to founder wasn’t just about applying skills, though. It was about purpose.

“It goes back to how I started looking for ways to teach her about her heritage and the world around her, but there just weren’t many authentic, hands-on resources for young children,” Whitney says.

“That gap sparked the idea for Global Sprouts. I realized if I wanted my daughter to grow up proud of her roots and curious about others, other parents probably did too. So I left the corporate world to build something that would help families everywhere raise globally minded, empathetic children.”

ICU, Hurricane Helene, and Building Anyway

The path from idea to execution wasn’t smooth. Whitney faced adversities that would have stopped most entrepreneurs before they started.

“The biggest adversities in my life became the foundation for everything I’ve built,” Whitney says. “Years ago, a car accident left me in the ICU and completely changed my perspective. It made me realize I had been living on autopilot and pushed me to start creating with intention.”

After recovering, Whitney opened and sold a fitness studio. Then came the challenge of balancing multiple roles simultaneously.

“Later, I opened and sold a fitness studio, was a new mom and became guardian to my teenage sister, and rebuilt after Hurricane Helene destroyed our home,” she explains.

Hurricane Helene hit Florida’s Gulf Coast in September 2024 as a Category 4 hurricane with 140 mph winds. While the storm made landfall in Florida’s Big Bend region, the Tampa Bay area experienced a devastating storm surge of 6-8 feet and widespread destruction. Over 1,000 people had to be rescued in the Tampa Bay area alone, to say nothing of the flooding as far inland western Northern Carolina.

For Whitney, Hurricane Helene didn’t just damage property. It destroyed her home while she was building a business.

“Each season taught me resilience, creativity, and empathy, which are the qualities that ultimately shaped Global Sprouts,” Whitney says.

That resilience shows in how she approaches the business itself. Global Sprouts isn’t built on the assumption that everything will go perfectly. It’s built by someone who knows how to rebuild when disaster strikes.

Authenticity Can’t Be Made with Google

In the crowded subscription box market, authenticity is Global Sprouts’ competitive moat. And Whitney protects that moat through the Cultural Ambassador Program.

“Authenticity is at the heart of everything we do,” Whitney says. “From the start, I knew Global Sprouts couldn’t just rely on online research or assumptions and we needed real voices and real experiences behind every kit. That’s why we created our Cultural Ambassador Program, partnering directly with people from each country we feature. They help choose the crafts, review storylines, and share traditions, language, and everyday details that make the experience genuine. We compensate them for their time and creativity, because it’s a true collaboration, not extraction.”

This approach costs more than having someone research countries online and create generic activities. But it creates something competitors can’t replicate.

“You can recreate the idea, but not the relationships or perspective behind it,” Whitney explains. “Our Cultural Ambassadors share lived experiences you can’t Google, and I approach every kit as both a founder and a mom, always asking, ‘Would I want my daughter to learn this?’ That mix of authenticity and intention is what makes Global Sprouts impossible to duplicate.”

The program ensures that each box goes beyond stereotypes and surface-level facts. When a box features Japan, it’s co-created with someone from Japan. When it features Costa Rica, it’s built with input from someone who actually lives that culture.

Whitney experienced this need personally during her travels, and it’s why this process is so much a linchpin to Global Sprouts. She says, “when I was traveling to all these countries, I was drawn to the small towns that aren’t tourist hotspots. My family traveled to Samara, Guanacaste in Costa Rica earlier this year and it was so fulfilling to visit local restaurants, watch my daughter play with local children on the playground, and hear stories from the people living there. That was a beautiful experience that furthered my thinking that everyone needs to be able to learn about the world around them, especially children!”

Those authentic experiences, not just guidebook summaries, are what Global Sprouts aims to deliver in every box.

Community Came First, Then Paid Media Second

Whitney’s Ferguson background shaped not just her B2B2C strategy but her entire marketing philosophy.

“It’s definitely a crowded space, but that just means you have to be intentional about standing for something real,” Whitney says about the subscription box market. “Most children’s boxes focus on entertainment or STEM learning, while Global Sprouts is rooted in culture, empathy, and connection. They are authentically created with our ambassadors so parents see the difference immediately.”

But even the most authentic product needs a go-to-market strategy. Whitney’s approach prioritizes community building over paid advertising.

“From a marketing standpoint, it goes back to community first, paid media second,” she explains. “We start local with schools and libraries so families can experience Global Sprouts firsthand before ever seeing an ad. That’s where my marketing background comes in: we build genuine awareness and trust through storytelling, then scale through targeted paid media and social proof. It’s a long game, but it creates customers who stay.”

This approach flips the typical startup playbook. Instead of buying Facebook ads to acquire customers quickly, Global Sprouts invests in partnerships with schools and libraries. Children experience the boxes in educational settings, then go home excited to tell their parents.

The result is customers who come pre-sold on the product because they’ve seen it work with their own children.

It’s slower than blasting paid ads. But it’s more sustainable and creates better unit economics over time.

Why Focus on Kids Aged 2-6?

“We focus on ages 2–6 because those early years are when curiosity and identity start to take root,” Whitney says. “Children at that stage are naturally open-minded and eager to explore, so it’s the perfect time to introduce them to different cultures. Our content is designed with that developmental window in mind and mindful of short attention spans, the benefits of sensory learning, etc. Every activity is simple enough for little hands but meaningful enough to spark connection, helping parents lay the foundation for cultural awareness that grows with their child.”

The boxes are designed around what Whitney calls “FAFO parenting”—giving children space to experience natural consequences and learn through exploration.

“FAFO parenting is about giving children space to experience natural consequences and learn through exploration which aligns perfectly with Global Sprouts,” she explains. “Our kits are designed to let children take the lead by trying, creating, sometimes making mistakes, and discovering what works along the way. It’s not about perfect crafts or memorizing facts but nurturing curiosity and problem-solving. When children are trusted to ‘find out’ for themselves they grow more confident and connected to the world around them.”

This philosophy resonates with parents tired of perfectionism and structured activities. The crafts in Global Sprouts boxes aren’t meant to look Instagram-perfect. They’re meant to be explored, experimented with, and yes, sometimes done “wrong.”

The age range also makes business sense. After mastering ages 2-6, Whitney has room to expand.

“In the next 3–5 years, our goal is to expand Global Sprouts to reach more age groups and represent even more of the world,” she says. The company is already testing interest in boxes for children ages 7 and older.

Representation Has To Be Felt, Not Just Seen

“Representation is built into every Global Sprouts kit,” she says. “We co-create each one with Cultural Ambassadors from that country to ensure the stories, crafts, and recipes reflect real life and not stereotypes. Families have shared that their children light up when they recognize a tradition or language from their own heritage, and others love that their children are learning about cultures beyond their own. That feedback reminds us that representation isn’t just seen but felt.”

One of the countries featured in Global Sprouts is Guam, allowing Whitney to share her own CHamoru heritage with other families. It’s the box she wished existed when her daughter was born.

This dual impact—children seeing their own culture represented while other children learn about it—is what makes the Cultural Ambassador Program essential. Without authentic voices, the boxes would just be another form of cultural tourism. But it’s with the collaboration with ambassadors that they become windows into lived experiences.

The Next 3-5 Years

Whitney launched Global Sprouts with 12 countries featured across different boxes. But the vision is much larger.

“We launched with 12 countries, but our vision is to grow to over 30, giving families a truly global learning experience,” she says. “We’re also developing new activities and resources for older children to continue building empathy and cultural understanding as they grow.”

The expansion isn’t just about more countries. It’s about reaching more children at different developmental stages. The company has already started gauging interest in boxes for ages 7 and older, recognizing that cultural education doesn’t stop at age 6.

But regardless of how many countries or age ranges Global Sprouts eventually covers, the foundation remains the same: authentic voices, hands-on learning, and materials that help children understand the world beyond their own experience.

“I wanted her to grow up knowing who she is, CHamoru, Dutch, and American, and to love that about herself from the very beginning,” Whitney says of her daughter. That personal mission became Global Sprouts’ broader purpose—helping every child know who they are while being curious about everyone else.

You can explore Global Sprouts’ full collection at globalsprouts.com or start a monthly subscription to bring the world to your doorstep.

Key Takeaways

Did you read this piece looking for tips on how to grow your own business? Here are some things that stood out to me.

Don’t wait for perfect conditions to start building.

Whitney went through a lot in her life, including a serious car accident, taking guardianship of her teenage sister, and losing her home to Hurricane Helene. And she credits these conditions with teaching her resilience, creativity, and empathy.

Deep knowledge requires compensation.

The Cultural Ambassador Program pays people for their time and expertise. It’s collaboration, not extraction. This creates a competitive moat competitors can’t replicate by Googling.

Corporate experience translates to startups.

Ferguson’s B2B2C model—build trust with influencers (contractors) who influence end buyers (homeowners)—applies directly to Global Sprouts’ school-first, parent-second approach. Your corporate skills might be more transferable than you think.

Start local.

For Whitney, she started reaching out to schools and libraries. She let families experience products firsthand. Then once she saw how things went, it was only then that she would amplify with paid media.

Subscription boxes are crowded. Stand for something real.

Entertainment and STEM are everywhere. Culture, empathy, and connection are rare. When the market is crowded, narrow your focus and own it completely, as Whitney did by doubling down on cultural authenticity through Global Sprouts.

You work a full-time 9-to-5 and rush home to eat dinner. Then you work until midnight blending essential oils, hand-bottling products, applying labels, and packing orders.

On weekends, you do more of the same. And on top of all that, you’re burning 8 to 10 hours every month just managing sales tax across 20+ states.

That was Jessica Rich’s life for months while building Bona Dea Naturals, her natural feminine health brand. Today, she’s sold over 150,000 bottles worldwide and earned more than 8,000 five-star reviews on Amazon. But the journey from chronic health struggles to a thriving women’s wellness business wasn’t glamorous. It was grueling, uncertain, and required her to push through moments when most people would have quit.

This is the story of how one woman turned her personal pain into a science-backed solution that’s helped thousands of women. And it’s also a story of how she’s challenging the stigma that all too often surrounds women’s intimate health.

Jessica Started By Solving Her Own Problem

Jessica Rich dealt with a lot of women’s health issues before building Bona Dea—the sort that seemed constant and awfully difficult to resolve. And she is refreshingly forthright and honest about this on the about page of Bona Dea.

As time went on, Jessica found herself distressed by how traditional pharmaceutical treatments kept failing her. She was tired of temporary fixes to recurring infections and wanted something that actually worked. And she wanted this to be done ideally without relying on constant medication.

That’s when she started researching essential oils and their antifungal and antibacterial properties. What began as curiosity quickly turned into deep research. “It felt like going down a rabbit hole,” Jessica says, “pulling late nights combing through medical journals and university studies about essential oils with antifungal and antibacterial properties.”

Here’s the thing: Jessica didn’t have a background in medicine or science. She’d worked in education and nonprofits. Sorting through dense, complex research text took serious effort. But what surprised her most was “how much research already existed, but how little of it had made its way into practical, accessible products for women.”

There was a clear gap between what science showed could help and what was actually being sold.

After months of trial and error, Jessica formulated a recipe that worked better than she imagined. She made her first homemade spray and shared it with friends who were struggling with the same recurring infections she’d dealt with for years. They experienced real relief, just like she had. They urged her to try selling it.

When Jessica made her very first Etsy sale, something clicked. “It hit me: this wasn’t just a personal fix. It was a solution other women had been desperately searching for too.”

In March 2016, Bona Dea Naturals was born.

The Grueling Reality of Scaling Solo

Those early days were a blur of long nights and relentless hustle. Jessica was still working her full-time job. A typical day looked like this: work 9 to 5, come home, eat dinner quickly, then spend the rest of the evening blending, bottling, labeling, and packing orders until late at night. Weekends were more of the same.

She was doing everything herself. Bookkeeping. Shipping. Customer service. Sales tax management. Advertising. Inventory tracking. All of it.

Jessica kept trying to make things more efficient. She went from hand-pouring to acquiring a small machine that would exactly fill each bottle with 2oz of product. She’d been placing each label on each bottle by hand, so she bought a label machine that made the job quicker and more consistent.

But she still couldn’t keep up.

She was managing sales tax across 20+ states where Amazon had inventory placed through FBA. That alone was eating up 8 to 10 hours every month. Every state seemed to have different rules, and it was overwhelming.

And as if that’s not enough, there was also a creeping sense of imposter syndrome.

The tipping point came when she was consistently spending more time on the business than on her actual job—and still couldn’t keep up with demand. She realized she either had to scale differently or burn out completely.

What kept her going during those exhausting months? The reviews. The stories women shared about finally finding relief after years of failed treatments. “That’s when I realized my private struggle could become something bigger—a business with the potential to help thousands,” Jessica says.

But something had to give.

From Kitchen to Contract Manufacturer

Moving from her kitchen to working with a contract manufacturer was the biggest and scariest leap Jessica took.

“I was terrified of losing control,” she says, “of handing my formula over to someone else and worrying it wouldn’t come out the same.” She also had no idea how to navigate purchase orders, freight terms, or minimum order quantities. It was a completely new world.

What Jessica learned is that “manufacturers aren’t just vendors, they’re partners.” Choosing the right one was critical. It forced her to think about her business in a more professional, scalable way.

The moment that shifted her mindset wasn’t abstract—it was physical. “Honestly, receiving the first pallets of my product from a manufacturer instead of seeing rows of bottles lined up in my kitchen made it real for me,” Jessica says. “That physical shift made me see the business as something much bigger than just a ‘side hustle.'”

For other founders dealing with imposter syndrome, Jessica offers this advice: “Don’t wait for someone else to validate you. Growth doesn’t always feel glamorous, but if customers keep coming back and your product works, you’re already the real deal.”

That transition from handmade to contract manufacturing unlocked everything. It gave Jessica the capacity to actually scale. And shortly after, she invested in automation software to handle multi-state sales tax compliance. That was a game-changer. It freed her to focus on growth instead of drowning in spreadsheets.

Mastering Amazon (And Learning Its Dark Side)

In the early years, Amazon felt like a golden ticket. Jessica’s products gained traction fast. Orders poured in. The numbers validated her passion and her product.

But over time, she learned how fragile that success could be.

Without warning or clear explanation, Amazon would remove listings—products she had poured months of research and development into. She’d be left scrambling to navigate vague policies and opaque support channels. Each takedown meant thousands in lost revenue and weeks, sometimes months, of uncertainty. And as the only employee of her company, she bore the full weight of those disruptions alone.

“The pivot came after realizing how fragile my Amazon-dependent business really was,” Jessica says. “One policy change could wipe out months of work and revenue overnight.”

Still, Amazon taught her invaluable lessons. Here are the three most critical things she learned about succeeding on the platform:

Reviews are everything.

“Even a tiny bump in rating can mean a 20–25% swing in sales,” Jessica explains. Customer feedback wasn’t just social proof—it directly impacted her revenue.

Never rely on Amazon alone.

It’s unpredictable. Policy changes, listing removals, and algorithm shifts can tank your business overnight. “Build your own channels and stability outside the platform,” she advises.

Master PPC ads.

Once you understand how to run Amazon advertising campaigns effectively, you gain far more control over your success.

Despite the challenges, Amazon remains a significant revenue driver for Bona Dea Naturals. But Jessica knew she needed to diversify. She couldn’t let one platform hold all the power.

Breaking Taboos & Marketing Feminine Health in a Censored World

Marketing women’s health products means constantly walking a tightrope between honesty and censorship.

So in that spirit, let’s speak very plainly.

Platforms flag words like “vagina” or “menopause” as inappropriate. That forces brands to use vague euphemisms. “Which is not only frustrating but medically irresponsible,” Jessica says.

Think about that for a second. Medical terms—accurate, clinical language that describes human anatomy and health conditions—get censored. It pushes legitimate healthcare conversations into the “adult” category, as if discussing your own body is somehow inappropriate.

Jessica refuses to play that game. Bona Dea Naturals stays authentic by “insisting on accurate language, fighting against mislabeling that pushes healthcare into the ‘adult’ category, and reminding women they deserve clear, stigma-free information.”

As she puts it: “Breaking taboos starts with saying the words out loud—and refusing to let algorithms dictate our conversations about health.”

The strategy has worked. Jessica has built deep trust with her community by being honest, responsive, and personally engaging with customers—even when the feedback is tough. She’s transparent about ingredients, product limitations, and the challenges of working in women’s health.

The most common customer feedback she receives? Some version of “this finally gave me my life back.”

Women share stories about finally finding relief after years of failed treatments. That level of vulnerability shaped how Jessica approaches everything. “I don’t chase trends,” she says. “I look for gaps where women are underserved and where science-backed natural solutions can make a real impact.”

As conversations around periods, menopause, and hormonal health have become less taboo, women feel more empowered to share their own experiences. That’s why Bona Dea Naturals’ reviews are so open and detailed. Jessica created a space where women don’t have to whisper about their health.

From a Single Product to a Women-Owned Marketplace

Two major realizations led Jessica to pivot Bona Dea Naturals from a single-product brand to a curated marketplace of women-owned wellness brands.

First, she saw how fragile her Amazon-dependent business really was. One policy change could wipe out months of work and revenue overnight.

Second, her customers were asking for natural solutions she couldn’t create alone. They trusted her judgment and wanted more options that aligned with the same values—science-backed, transparent, and effective.

Jessica realized that many small businesses focus on specific feminine issues but often lack the resources to provide a comprehensive catalog of products. She set out to curate the very best from ethically responsible, women-owned businesses that emphasize natural ingredients and nontraditional healing methods.

Her selection philosophy? “I view it like building a library: every product has to serve a purpose, fill a gap, and align with the overall mission of empowering women’s health.”

The Bona Dea Naturals marketplace now features products addressing often-overlooked issues: PCOS, endometriosis, hormonal balance, UTIs, incontinence, low libido, vaginal dryness, perimenopause, postpartum concerns, and menstrual health.

It’s a way to give women more options while creating “a more sustainable, community-driven business.”

Two years into this shift, Jessica’s online store is growing steadily. Customer engagement is deeper and more meaningful. While Amazon sales still account for the majority of her revenue, she’s steadily reducing her dependency and building something more sustainable: a brand that reflects her values and empowers a broader community.

A Decade of Lessons Learned

After nearly a decade of running Bona Dea Naturals, Jessica has strong opinions about what it really takes to succeed.

“If I had to give just one piece of advice, it would be this: resilience is everything,” she says. “After nearly a decade of running my business, I’ve realized that success doesn’t necessarily come down to having the best idea, the most funding, or even the perfect strategy. It comes down to your ability to keep going when things get hard—and they will get hard.”

There will be moments where you feel completely overwhelmed, like you don’t know what you’re doing, or like the next hurdle might be the one that breaks you. “And that’s exactly the moment when most people quit. That’s why so many businesses don’t make it—because it got too hard, and they decided they were done.”

But the ones who succeed? They push through. They figure it out. They fight for it.

Jessica admits that one of her biggest early weaknesses was taking everything personally. Because the business was so personal—born out of her own struggles—it felt like an extension of who she was. She took every negative review personally, resisted outside advice, and felt like she had to do everything herself because no one else could possibly understand it the way she did.

She’s still working on that. But she’s learned to separate herself from the business just enough to make better decisions.

On the product side, Jessica has always been adamant about balancing “natural” positioning with real efficacy. “I lead with results,” she says. “Yes, the ingredients are natural, but they’re also science-backed.”

She’s invested in clinical testing, like RIPT trials, to prove safety. And ultimately, thousands of detailed reviews speak louder than marketing ever could.

“Natural doesn’t mean ‘less effective’—it means effective without unnecessary chemicals.”

What’s Next For Bona Dea?

Today, Bona Dea Naturals has sold over 150,000 bottles worldwide. The brand has earned more than 8,000 five-star reviews on Amazon. What started as a desperate search for personal relief has turned into a thriving business helping thousands of women.

But Jessica’s vision goes beyond sales numbers.

“My vision is to build Bona Dea Naturals into the go-to destination for natural women’s wellness—not just a product brand, but a marketplace and community,” she says.

More broadly, she wants to help normalize the conversation around intimate health. “So that women no longer have to whisper about yeast infections or hormonal imbalances,” Jessica explains. “If we can replace stigma with science, honesty, and empowerment, we’ll have changed not just the marketplace, but the culture.”

It’s an ambitious goal. But if anyone can do it, it’s someone who spent months combing through medical journals with no science background, hand-bottled hundreds of units while working full-time, and refused to let Amazon’s algorithm or platform policies dictate how she talks about women’s health.

You can follow Bona Dea Naturals on Instagram or shop the full collection on their website and Etsy.

Key Takeaways

Did you read this piece looking for tips on how to grow your own business? Here are some things that stood out to me.

Start with your own pain point.

The best products often solve problems you’ve experienced yourself. Your authenticity shows through, and you understand your customer better than anyone else could.

Science-backed doesn’t mean pharmaceutical.

Invest in research and testing to prove natural ingredients work. Jessica spent months reviewing medical studies before formulating her first product, and she continues to invest in clinical testing like RIPT trials.

Don’t rely on a single sales channel.

Amazon taught Jessica that platform dependency is dangerous. One policy change, one listing removal, and your revenue can disappear overnight. Diversify early, build your own channels, and create stability outside any single platform.

Master the operational basics.

Tools and automation free you to focus on growth. For Jessica, investing in sales tax automation software was a game-changer that gave her back 8-10 hours every month. This ended up being time she could spend building the business instead of drowning in compliance.

Be clear in your messaging.

Women’s health is taboo and a lot of brands are tempted to use euphemisms for medical terms. But Jessica’s audience wanted (and needed and, frankly, deserved) accurate language. For Jessica, it was important to remind women they deserve clear, stigma-free information about their own bodies.

Resilience beats funding.

Most businesses fail because founders quit when it gets hard, not because they lacked resources. Success comes down to your ability to keep going when you feel overwhelmed, uncertain, or like the next hurdle might break you.

Build partnerships, not dependencies.

Whether it’s manufacturers or platforms, choose partners who align with your mission. Jessica learned that manufacturers aren’t just vendors. They’re partners in building something sustainable and scalable.

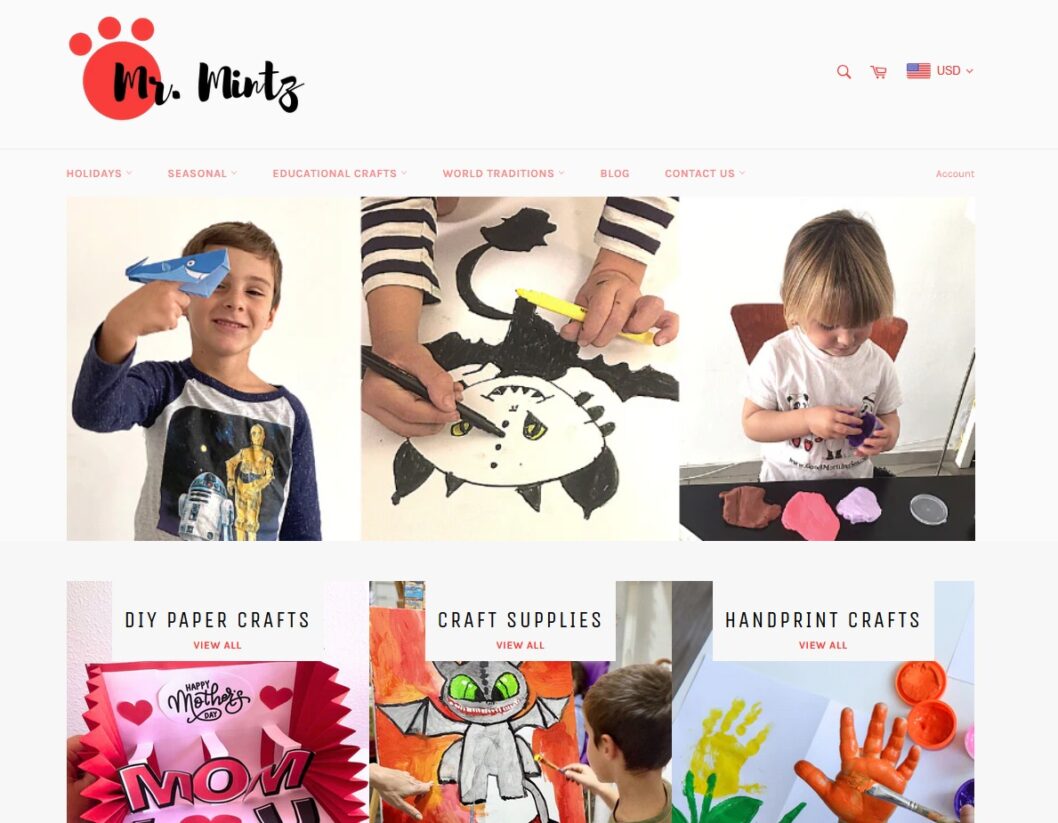

The Mr. Mintz brand sounds like it should be about a dad who creates crafts with his kids. And in a way, it is—but the business brain behind it belongs to Lena Mintz.

Lena Mintz spent her career in corporate PR and advertising at companies like Mail.Ru Group, shaping stories for C-level executives. Then she had two babies back-to-back, the pandemic hit, and when it was time to return to corporate life in 2020, something didn’t feel right. She took an Etsy workshop almost by accident, started researching digital printables, and within months launched her first products.

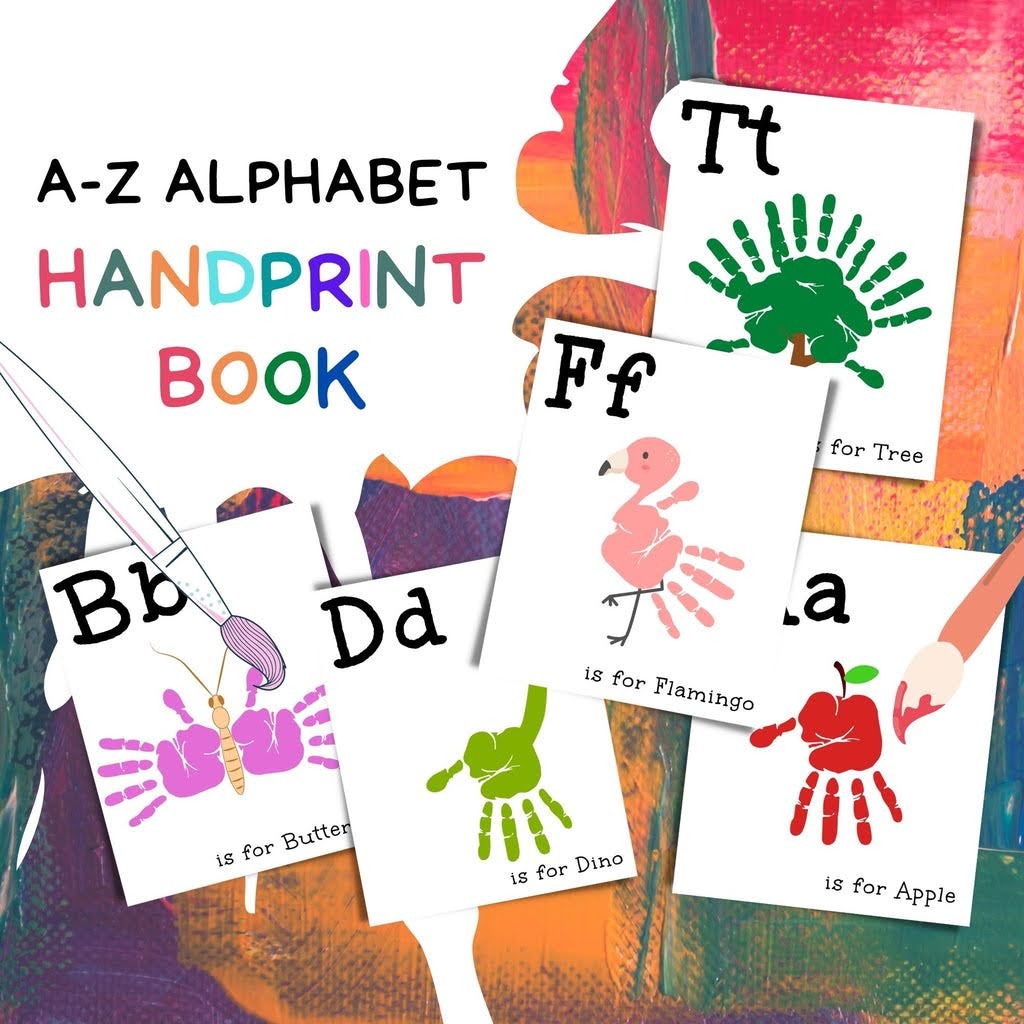

Today, Mr. Mintz serves families and teachers worldwide across Etsy, Shopify, Teachers Pay Teachers, Made By Teachers, and TES Resources. The brand has 75,000+ Facebook followers and generates over 1 million monthly Pinterest views, all of which was done organically and without so much as a dollar of advertising. They offer hundreds of printable handprint crafts, finger puppet templates, and educational activities in multiple languages.

This is the story of how a former PR executive turned a $2.99 digital printable into a multi-platform family business—and why she describes it as building a “small spaceship” that’s solid enough to keep flying even when turbulence hits.

A Family Business With a Twist

“I’ve always been the one with the business background, and my husband has always spent more time with the kids than I did,” Lena explains. “Even when I was on maternity leave from my corporate job, I didn’t exactly pause my career. I started working on consulting projects—small startups, early-stage brands—things I could do from home, in my own rhythm.”

That flexibility became essential during the pandemic when everything was uncertain. Eventually, official maternity leave ended and Lena faced a decision: return to the 9-6 corporate life or build something of their own. They chose the second option.

“I had spent my whole career behind the scenes, doing PR for C-level executives and business leaders. Always shaping someone else’s story,” Lena says. “When we began dreaming up the brand, it made perfect sense to put the dad in the spotlight. It wasn’t just cute branding. It was true to life.”

The name Mr. Mintz came easily. It felt fun, trustworthy, and it sure didn’t hurt that it was their actual last name!

Lena creates and manages the stores, handles product development, SEO, and launch schedules. Her husband shoots and edits videos, tests crafts with the kids, and handles photography and social media visuals. Their kids are the ultimate product testers.

They’ve never worked with agencies, designers, or ad specialists. Everything has grown organically—Facebook (75K+), Pinterest (over 1M monthly views), YouTube (11K+)—all built from scratch with no ad budget.

The Accidental Entrepreneur

Lena didn’t plan to leave corporate PR. “But two things changed everything: I had two babies back-to-back, and then the world shut down.”

During maternity leave, she stayed partially active—helping startups with communications projects. But once leave officially ended, she faced a decision. She had meetings with the team she’d be rejoining. It didn’t click.

“The idea of spending my days away from the kids, away from this rhythm we had built, felt wrong,” she says. “And this was 2020—everything was uncertain. Lockdowns. School closures. No one knew what would happen next.”

Then, almost by accident, she came across a workshop on building an Etsy shop. She didn’t even know what she’d sell—she just felt a pull. She signed up, started researching, learned everything she could.

“It felt risky, but also incredibly energizing. I handed in my resignation, closed the door behind me, and gave myself full permission to try something new.”

Validating the Product & Finding the Handprint Niche

Lena’s “aha moment” wasn’t dramatic. It was methodical. She joined a seminar about dropshipping—not because she wanted that business model, but because she was searching for direction. The dropshipping model didn’t resonate, but the tools did.

“I started using eRank and other tools, just digging, exploring, narrowing down,” Lena says. “I wasn’t brainstorming ideas out of thin air—I was sifting through data.”

Then she came across the handprint niche. “I had no idea how strong the demand was until I saw the numbers. I thought, wait a second… this isn’t just a cute idea. This is a real, emotional product that parents are actively searching for.”

She focused on long-tail keywords, testing smaller sub-niches like custom versions, specific holidays, different languages. The first real sale came surprisingly quickly. One product turned into ten, then fifty.

The Multi-Platform Strategy, or “Building a Small Spaceship”

Mr. Mintz started on Etsy. “It’s uniquely beginner-friendly. You can open a shop, upload a few listings, and get your first sales surprisingly fast, even without a social media following or a budget.”

Shopify came next, growing slowly. “Unlike Etsy, there’s no built-in audience, no marketplace search. You have to drive the traffic yourself.” Now their traffic is consistent—split about 50/50 between Pinterest and organic Google search.

The decision to expand to Teachers Pay Teachers, Made By Teachers, and TES wasn’t about chasing revenue—it was about reducing risk.

“Etsy’s algorithm can be unpredictable. One month a product is your best seller, the next it’s buried—even if demand hasn’t changed,” Lena says. “So for me, it made more sense to reuse the assets we already had and upload them to multiple marketplaces. One platform dips, another might rise.”

Some people say she’s spreading herself too thin. But Lena chose this approach of diversifying channels deliberately.

“I like to think of it as building a small spaceship—not the fastest, maybe not the sleekest, but one that’s solid enough to get off the ground and keep flying, even when turbulence hits.”

Why The $2.99 Pricing Strategy Works

Digital printables seem simple to price because there’s no inventory and no shipping. But the reality is complex.

“The first layer is fees,” Lena explains. “Etsy takes a cut for just about everything—listing fees, transaction fees, payment processing. While 20 cents per listing doesn’t sound like much, it adds up quickly when you’re running hundreds of active listings.”

Pennies add up a lot when you’re selling a $2.99 product. It doesn’t leave much breathing room.

“The second layer is scale. These products are priced low, so success relies on volume. You need to sell a lot—and have a lot—to make meaningful income.”

Then there’s competition. Lena uses eRank to analyze what other creators charge. Some sellers price crafts at $1.00, but between fees and taxes, they’re walking away with pennies.

“It’s not sustainable, and frankly, it’s not really a business model—it’s more like sabotage.”

Pricing comes down to a balance between platform math and customer perception—finding that sweet spot where the product is attractive, affordable, and still worth the effort.

Protecting Intellectual Property

“In the niche I work in, it’s incredibly hard to create something so unique that it could be properly protected,” Lena admits. “Most printable crafts are simple, affordable, and easy to replicate with just a few tweaks.”

Legal protection is often not worth the effort. Even when you spot blatant copying, lawyer costs almost always exceed the product’s value.

“We’re currently in the process of trademarking our brand, Mr. Mintz, and that’s really the only thing we can protect for now.”

The rise of AI design tools made it trickier. “Before, you had to run ahead of your competitors. Now, you have to fly. But I’ve accepted that as part of the game. You can’t build a business by constantly looking over your shoulder. You just stay one step ahead—create better, create faster, and keep innovating.”

There are bright spots. On their own site, parents buying for multiple kids sometimes manually increase the quantity, allowing you to choose two or three licenses without being prompted.

“It’s rare, but it happens, and every time it does, I smile. It’s a reminder that people do value creative work.”

Another way they protect what they do is through customization. “We once got a message asking us to add a mustache to our firefighter craft. Another time, a customer asked us to replace a spotted cow with a brown one—because their dad is a farmer. They wanted the gift to feel truly personal. And we did it. That’s not something you can steal with a screenshot.”

Listening to TikTok and Teachers

Mr. Mintz doesn’t create products based on gut feelings. They follow demand and trends.

“A couple of years ago, when we were building our Father’s Day collection, we had an amazing flow of feedback from TikTok,” Lena recalls. “We’d post a new craft idea—like a handprint for a firefighter dad—and people would immediately comment: ‘What about a musician?’ ‘Can you make one for a doctor?’ ‘My dad works in IT—can you make one for that?'”

So they did. Several of their most popular templates were born from real back-and-forth with real parents.

They also use data, including tools like eRank to see what people are searching for. But the most meaningful ideas come from conversations. “Our audience builds this catalog with us—they’re not just buyers, they’re collaborators.”

One unexpected success was their Sukkot craft. Lena saw a question in a community group about decorating a sukkah and quickly created two handprint crafts, one with Hebrew text. Posted just two weeks before the holiday, they started selling immediately across all platforms.

“For something I designed myself in a single evening, that kind of response felt like a quiet win. Sometimes, being small means being quick—and that’s a competitive advantage.”

The Multilingual Expansion

Mr. Mintz offers products in Spanish, Hebrew, Arabic, German, and Indian themes.

“I lived in Israel for a few years, so when I started Mr. Mintz, it felt natural to include Jewish holidays and symbols,” Lena explains. Living in Spain now, she sees how important bilingual resources are, especially in the U.S. where many families have Hispanic roots.

Sometimes ideas come from customers. The German versions were born because a customer messaged: “We love your products—but it’s frustrating that we can’t use them in German.” So they worked with a native speaker to adapt the designs.

“Multilingual crafts help children connect with their heritage—or learn about others. And that’s something we deeply care about: making every child feel seen, no matter what language they speak or what traditions they celebrate at home.”

Final Thoughts On A Spaceship Still Being Built

Like so many creative companies, Mr. Mintz has more ideas than time. They’re exploring ways to launch a subscription with exclusive printables. TikTok is untapped. The Pinterest audience is there, they just need to catch up. The question is: what should happen next?

The website was restructured this summer to be more Google-friendly. Step two is preparing for AI-driven discovery, which means rethinking content structure and how their work surfaces in AI tools.

“It’s a whole new frontier, and I believe that’s where the next big wave of growth will come from.”

Her advice for aspiring digital product creators: “You don’t need ten products, or a big launch, or even a perfect idea. You just need something that feels right to you and the courage to publish it. Sometimes you think it’s a great idea, and it flops. Sometimes you post something simple—and it takes off. You can’t know until you try.”

She emphasizes that you don’t have to quit your job or hire experts. “Any business—especially digital—can start as a side project. The barriers are low, the startup costs are tiny. No storage, no shipping labels, no returns—just creativity and curiosity.”

You can explore Mr. Mintz at mr-mintz.com, browse their Etsy store, or find them on Teachers Pay Teachers.

Key Takeaways

Did you read this piece looking for tips on how to grow your own business? Here are some things that stood out to me.

Corporate skills transfer to entrepreneurship.