How to Start a Subscription Box Business in 10 Easy Steps

Subscription boxes seem unstoppable now. But as recently as 2010, the business model barely existed. Rather, it was around 2011 when subscription boxes started to take off, with brands like BirchBox, Dollar Shave Club, and NatureBox becoming household names.

According to Market Research Future, the US subscription box industry was valued at $13.5 billion in 2022 and is expected to grow to $44.5 billion by 2032, which is more than triple!

Because subscription box businesses are so hot right now, a lot of people want to cash in. You might be one of them since you’re reading this article! So let’s talk about how you can start a subscription box business in 10 easy steps.

1. Understand the basics of subscription boxes.

As with any business, you need to thoroughly understand the market before you jump in. To help you do that, we’re going to go over the basics of the subscription box business model. This will help you determine whether it’s right for you.

What’s a Subscription Box?

Easyship said it best: “subscription boxes are recurring and physical deliveries of given products which are packaged with the aim of offering consumers additional value and a unique experience, added to the actual product contained within each box.”

Basically, subscription box buyers receive boxes full of unique and interesting products on a regular basis. Subscribers pay for a recurring subscription and receive boxes on a regular basis, usually every month. The boxes are full of physical items, many of which are surprises carefully curated to please the subscriber. Many subscription boxes show customers how much they saved on the retail value of the items contained within.

Last but not least, subscription boxes are almost always gorgeous. The packaging and the contents are often beautiful and made specifically for people to record unboxing videos.

Benefits of the Subscription Box Business Model

From a business perspective, there are a lot of benefits to the subscription box business model. But we wanted a first-hand perspective here, and for that, Ben Ajenoui, Marketing & Managing Director at the eCommerce platform, Opencart, was happy to oblige.

“Our move into subscription box services was driven by the growing demand for recurring revenue models in the retail space,” says Ajenoui. “Many of our users were asking for more streamlined ways to offer subscription-based products, and we saw an opportunity to support them.”

It’s no surprise that Opencart transitioned into the subscription box space when you consider the value of recurring revenue. The following five facts, taken together, make a really strong case for starting a subscription box business:

- Since boxes are sold on a subscription basis, revenue is much more predictable than with most kinds of eCommerce.

- Because subscriptions are recurring transactions, the average customer has a much higher lifetime value than other businesses.

- It’s harder to win a subscriber than it is to win a buyer, but once you do, the odds of retention are much higher.

- Subscription boxes are all about the unique experience, which gives companies great opportunities for branding.

- Because subscription boxes are sent out around the same time of the month in large batches, this simplifies shipping and fulfillment.

Disadvantages of the Subscription Box Business Model

Of course, the subscription box model isn’t perfect. We can think of five negative considerations that you need to weigh in as well.

- According to Pitchbook, the amount of venture capital going into subscription box startups has gone down in the last few years. This could be a sign that the subscription box boom is over. Alternatively, it could be a consequence of massively overhyped companies like Blue Apron going downhill, but not an indicator that the industry at large is failing. Make of it what you will.

- To prepare subscription boxes to send, you need a lot of upfront capital to begin with.

- Subscription boxes live and die on their ability to seem luxurious and unique. That means you need a strong understanding of the fundamentals of marketing and branding to succeed.

- Because subscription boxes have become so popular, there is a lot of competition.

- Much of the magic of subscription boxes stems from the novelty of the items in them. That means when the novelty wears off, so does the perceived value of the subscription box.

There are also some operational challenges to consider as well. Among them, Ajenoui lists “recurring billing, [setting up] flexible product options, and [implementing] advanced customer management tools.” Before getting into the subscription box business, it’s worth considering if your team has the operational chops to set all of this up.

2. Identify a real market need.

In order to build a successful business of any type, you need to identify real needs in the market and come up with a wait to meet them. Otherwise, people have no reason to want to buy from you at all!

This is especially true in the subscription box business model. The reason for this is because getting someone to sign up for a subscription is harder than getting them to sign up for a single purchase. That means your subscription box needs to be so compelling that it overcomes customers’ objections so that they do not hesitate to subscribe.

“Convenience, personalization, and the excitement of regular deliveries” rank high in terms of customer values, according to Ajenoui. As you work on the particulars of your subscription box model, it’s worth considering how these values intersect with the kind of products you sell.

3. Research your competition and find a unique niche.

Because the subscription box business is fairly crowded, you need to find a niche that stands out among similar subscriptions. Your customers have lots of different options, so you need to provide something popular in a way that no one else is. This is where market research is essential!

If you want to stand out among your competition, don’t try to create a new product entirely. It’s much easier to deliver better quality products than your competition than to completely forge your own path. One way that you can do this? Find good suppliers and form great relationships with them.

4. Figure out what to put in the subscription box.

At this point, you will want to figure out what your subscription box itself will be like. Subbly suggests considering the following factors:

- Pricing

- Number of items

- Type of products and their packaging

- Size of the box

- Design and aesthetic

- Engagement experience

- Written content and packing information

Naturally, this will be different for every industry and for each type of box. What you want to do here is figure out how to take several different items and figure out how you can tie them together and create a unique experience for the box opener.

5. Master the unboxing experience.

Much of the magic of subscription boxes comes from the feeling your subscribers will have when they are opening the box. There is a reason why many people take videos of themselves unboxing subscription boxes and post them online. There’s a reason people watch these videos, too – vicarious pleasure is a very real thing and it compels many new people to subscribe to your box!

So how do you actually do that? We have a few suggestions:

- Use custom packaging so that when your box arrives in the mail, people are immediately excited about it.

- Pack the boxes in such a way that not all items are seen at once. One way you can do this is by covering the contents with a thin sheet of cardboard and putting a small letter on top for people to read before opening the rest of the box.

- Make sure the individual items themselves are bright and colorful and that their packaging really stands out, making a feast for your subscribers’ eyes.

6. Set up the supply chain.

Understanding the supply chain is one of the key success factors for subscription box businesses. You need to make sure the boxes are a reasonable size and weight, so you need to have all that information from your item suppliers in order to proceed. Hopefully, you will also receive a discount on the items themselves so that you have a healthy profit margin. You may need to tweak the items in the box in order to get them to fit or to get the price to be reasonable.

It’s also smart to look into sourcing products from multiple regions. Nearshoring or dual-sourcing, which means sourcing products from two different countries, can help you avoid unexpected cost spikes if tariffs increase or trade disruptions occur.

Especially important to subscription box businesses is having good relationships with custom packaging providers such as Noissue or Arka. While custom packaging definitely costs more, remember that the experience is the selling point, not the items themselves which can all be purchased individually.

Lastly, you will want to work with a fulfillment company that you trust. Odds are, the items and packaging will arrive separately and in large quantities. While you can pack and ship your own items, companies like Fulfillrite can take care of that for you. In particular, preparing subscription boxes in advance would be considered a kitting project. As far as receiving the supplies themselves and then sending out the subscription boxes, both of those are very routine tasks that can be cost-efficiently handled by a fulfillment company on your behalf.

6.5. Watch out for increasing supply chain costs.

One more factor to plan for: rising supply chain costs. Tariffs on imported goods have increased unpredictably in recent years, and many subscription box companies are feeling the pinch.

“We’ve seen a noticeable uptick in landed product costs for our clients,” says Chris Rivera, CPA & Founder of The Ecommerce Accountants. “Especially those sourcing from China and Southeast Asia. Tariffs have compressed gross margins and forced many brands to rethink their sourcing and pricing strategies. This has been particularly disruptive for high-volume sellers in competitive niches where price sensitivity is high.”

“Tariff changes in 2025 have really pushed anyone shipping from China to rethink their numbers,” says Todd Stephenson, Co-Founder of Roof Quotes. “If you’re in that boat, it’s smart to talk with your suppliers and see if they can shift production to places like Vietnam or India. You can’t just sit back and hope things go back to normal, you have to plan like these tariffs are sticking around. That means adjusting your pricing and making sure your operations can handle higher costs.”

7. Start marketing your subscription box before launching the service.

Treat your subscription box service launch like you would any other product launch. You need to start marketing it long before you actually start shipping boxes. At a minimum, you need a good brand name, logo, and website. If you’re not sure where to start, you can always use Shopify.

Marketing for a service launch is more complicated than we can adequately discuss in a post like this, but we’ll give you a few tips here:

- Build your website with conversions in mind. Everything on your site needs to ultimately increase the odds that someone will subscribe to your service.

- Create a sense of urgency with special offers and landing pages. Getting new subscriptions is harder than retaining them!

- Remember the marketing funnel: first someone becomes aware you exist, then they become interested, they think about buying from you, then they ultimately choose to buy from you. Then after that, they choose whether or not to purchase from you again.

- Customize your boxes as much as possible.

- Build a mailing list.

- Start content marketing online, including guest blogging.

- Implement a referral program.

- Look into pay-per-click advertising on sites like Facebook, Instagram, and Pinterest.

If you want to research this subject in more depth, we stumbled across this fantastic guide that will show you how to market your subscription box!

When in doubt, consider the advice of Ajenoui. “The most effective strategy for acquiring subscribers has been offering a seamless, customizable experience.” Clearly, providing a good customer experience is not something that can be overlooked!

8. Figure out shipping and fulfillment.

We touched on this before, but it’s especially important. If you have 500 subscribers, that means someone will need to receive all your supplies and packaging, prepare the subscription boxes, apply postage, and then send them to your subscribers. You can do this yourself, but it makes a lot more sense to work with a fulfillment company since they specialize in handling large quantities of orders at once.

If you go through a fulfillment company, you don’t have to worry about assembling the boxes by hand. All you have to do is design the packaging, pick the items, and go find customers. Everything else can be taken care of for you, leaving you with a lot more time to find subscribers and make money!

9. Take feedback, make improvements, and retain customers.

As with any business, once you start shipping your first few subscription boxes, you will need to gather customer feedback. Customer retention is essential, so try to incorporate feedback as much as you can. Make improvements when they are recommended. In the long run, it will pay off!

When it comes to retention, Ajenoui advises offering “personalized engagement, exclusive offers, and flexible subscription management.” He later mentioned that “streamline your operations with a reliable platform is essential for scaling and long-term success.”

As you gather feedback, consider what questions you can ask to ensure that you are in line with Ajenoui’s thoughts on best practices.

10. Establish great customer service.

Customer retention is essential for a subscription-based model. That means that once you have started shipping boxes, you need to have excellent customer service in order to keep customers subscribed. Do anything and everything you can to keep customers happy. Be sure they can reach by phone, email, and – if you have the resources to adequately manage it – social media!

Final Thoughts

Subscription boxes provide customers with unique experiences and business owners with unique opportunities. If you can combine the ability to surprise and delight customers with pragmatic business expertise around matters like supply chain management, then this business model could work wonders for you. Just follow the tips above and you’ll be well on your way to success!

FAQ

How much money do I need to start a subscription box business?

Initial costs vary widely but expect $10,000-50,000 minimum. This covers inventory for your first few months, custom packaging, website development, marketing, and fulfillment setup. Factor in 3-6 months of operating expenses since subscriber growth takes time.

How do I price my subscription box?

A common rule is the 3x markup: if your product costs are $10, charge around $30. This covers packaging, shipping, customer acquisition, and profit margins. Research competitor pricing and survey potential customers to find the sweet spot between value perception and profitability.

What’s the biggest mistake new subscription box businesses make?

Underestimating customer acquisition costs and churn rates. Many founders assume subscribers will stick around longer than they actually do. The average subscription box has a 5-10% monthly churn rate, meaning you need continuous marketing investment to maintain growth.

Should I handle fulfillment myself or outsource?

Start in-house if you have fewer than 200 subscribers and adequate space. Beyond that, outsource to a 3PL experienced with subscription boxes. They understand the complexity of kitting multiple items and managing monthly shipping spikes.

How do I deal with seasonal demand fluctuations?

Plan inventory 3-4 months ahead and communicate with suppliers about expected volume changes. Consider seasonal product variations or limited-edition boxes to capitalize on peak periods. Some businesses offer gift subscriptions during holidays to boost revenue.

What if customers complain about receiving duplicate items from previous boxes?

Maintain detailed records of what each subscriber has received and implement systems to avoid repeats. Many successful subscription boxes create item pools for different subscriber tenure levels, ensuring longer-term customers get fresh variety.

Getting started in eCommerce can be tricky. Even with all the wonderful eCommerce software like Shopify and WooCommerce, it still takes hours of setup even if you’re tech-savvy. What if you just want to start selling online without all the hassle?

Thankfully, PayPal has a very user-friendly option for entrepreneurs with a single product to sell. The idea is simple: you set up a PayPal Business Account and then you add PayPal Buy buttons to your website.

Seriously, that’s it! The configuration couldn’t be simpler and it’s a great stopgap to use before your business is large enough to justify setting up something more permanent, like a Shopify store.

So without any more preamble, let’s talk about how you can add PayPal Buy buttons to your website.

1. Create a PayPal Business account.

Before you can follow any of the steps in this guide, you will need to set up a PayPal Business Account. You can do that by going here and following all the prompts.

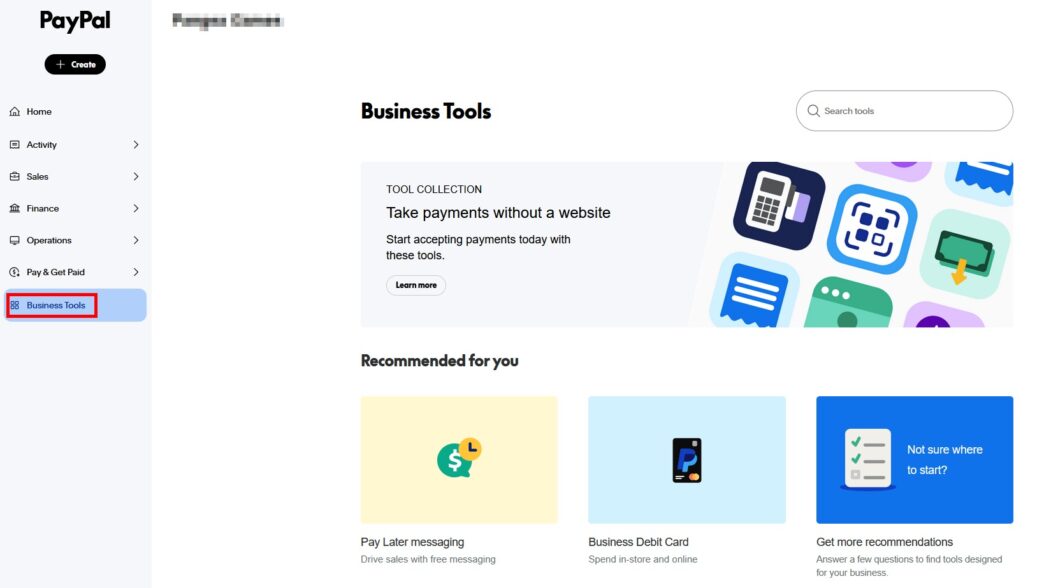

2. Log into your PayPal account and click Business Tools.

After you’ve set up your PayPal Business Account and logged in, you will see a home page like the one above. Click on Business Tools to proceed.

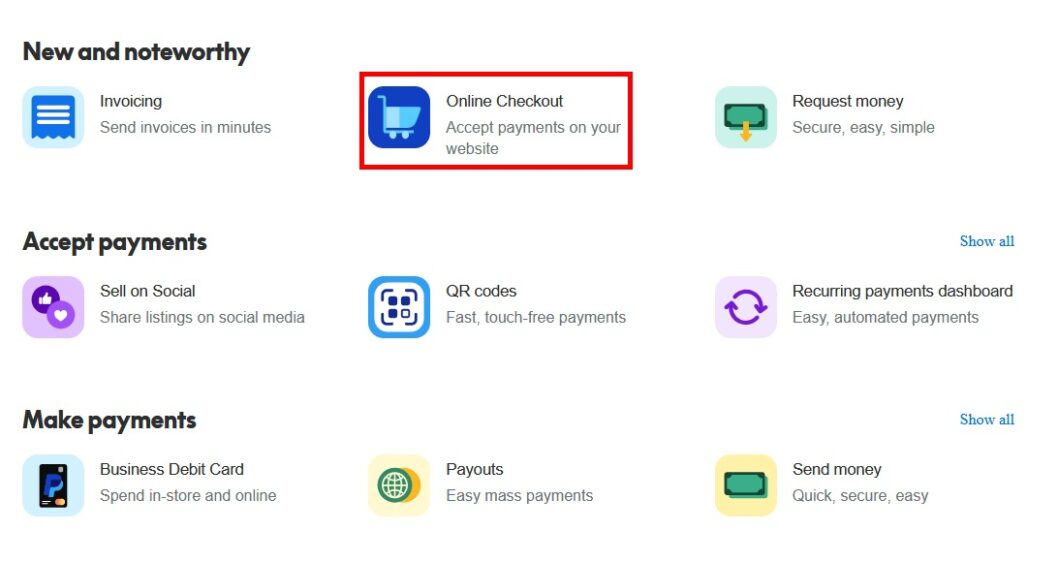

3. Scroll down and click Online Checkout.

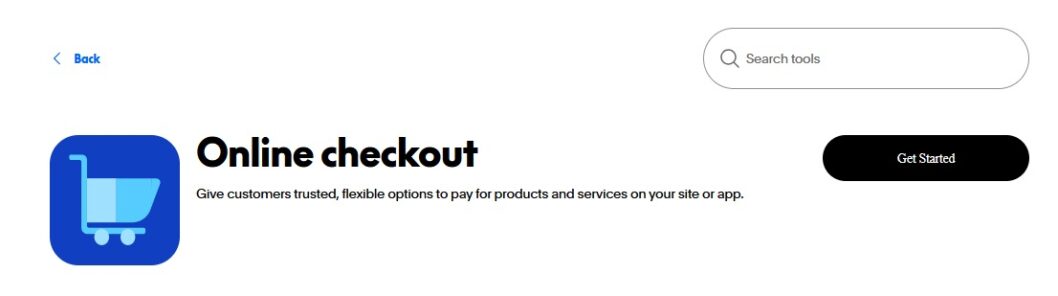

4. Click Get Started.

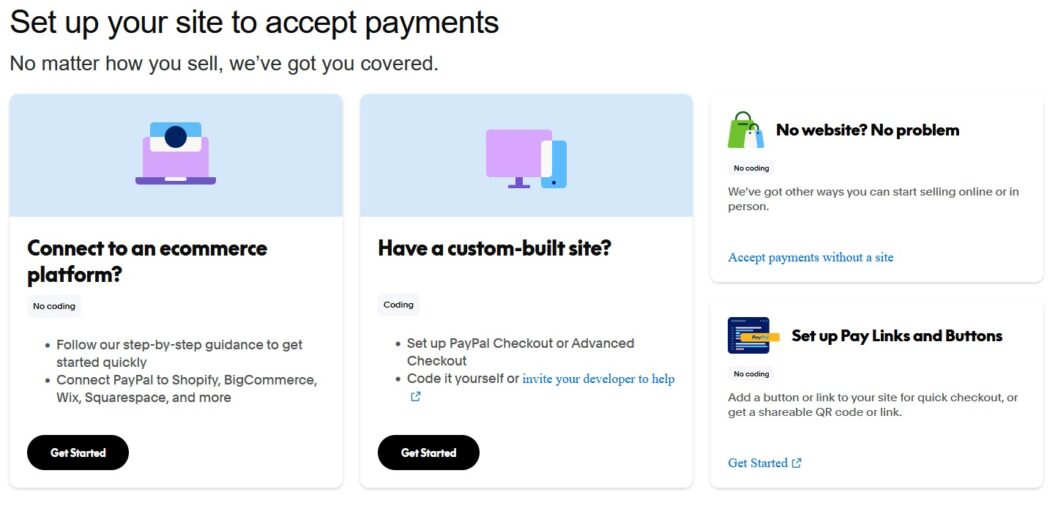

5. Click Set up Pay Links and Buttons.

At this point, please note that you have a lot of options for integrating PayPal onto your store. When you click on Set up Pay Links and Buttons, you will have a chance to configure buttons for different products in different styles. At the end of the process, you will receive an HTML code which you will paste into your website.

If you are using a major platform like WooCommerce or Shopify, you may want to check Connect to an ecommerce platform and follow the steps provided by Shopify. If you’re custom-coding your site, Have a custom-built site is probably the better option.

If you don’t have a website and you simply need a very easy page for payments, click Accept payments without a site in the No website? No problem section.

The rest of this guide will talk about what happens when you click Set up Pay Links and Buttons.

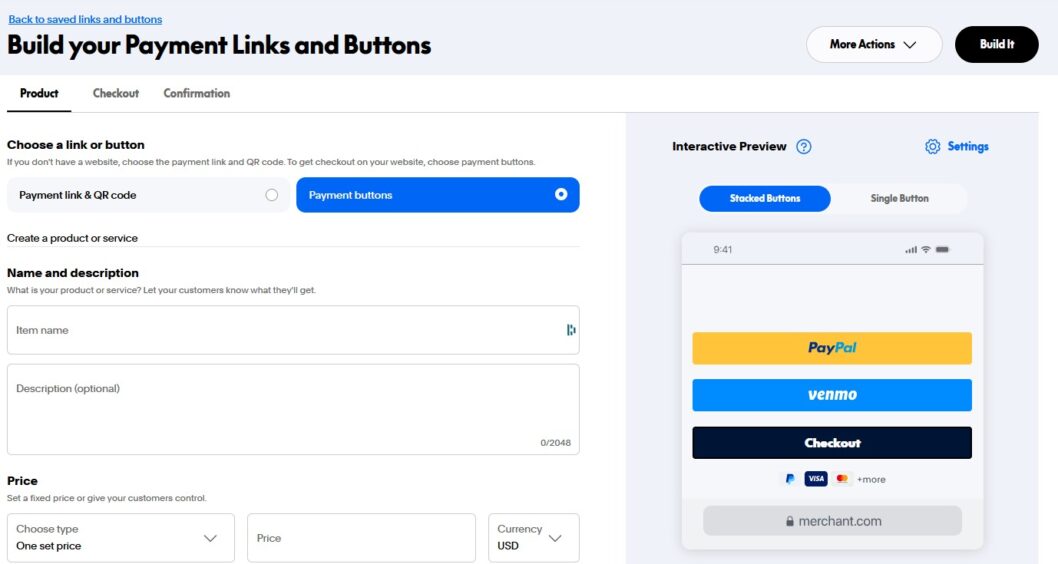

6. Select Payment Buttons.

When you click Payment Buttons, you will have a chance to setup a payment button for different products or services in a style of your choosing. If you don’t have a website, you might prefer the Payment link & QR code option instead.

In the steps to follow, we will assume you click Payment Buttons.

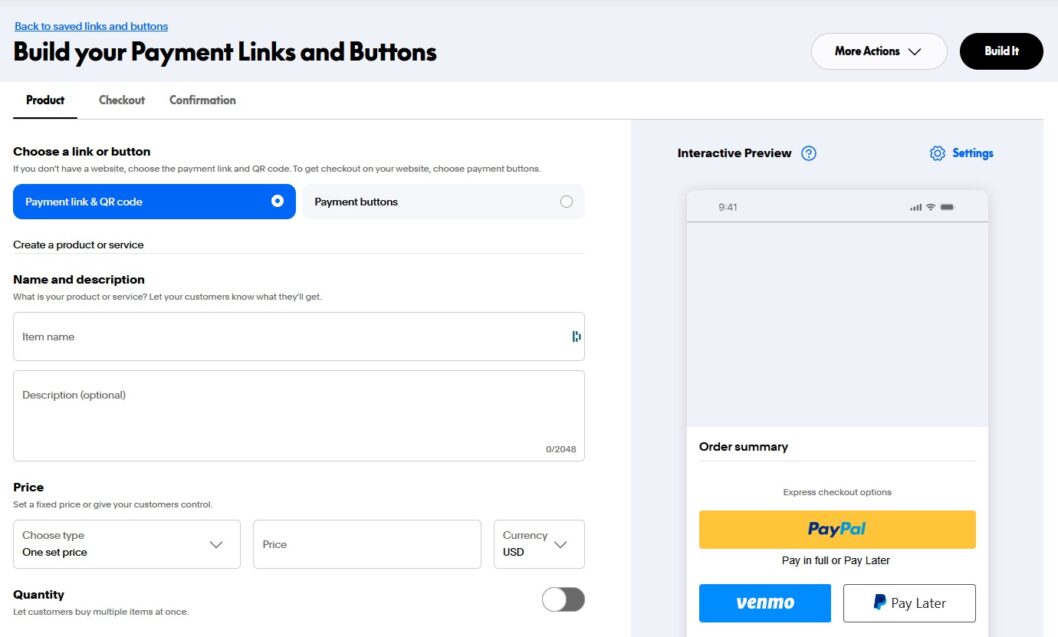

7. Enter product details and customize buttons and thank you page.

To create and customize your button, there are several fields you can fill out.

- Item Name and Description: Enter an item name and an optional item description.

- Price: Set a price, which can either be “one set price” or “customer set price” which allows customers to set their own price (appropriate for tipping or situations where partial payment is acceptable.

- Quantity: You can also optionally set Quantity to allow customers to buy multiple items at a time up to a maximum limit.

- Images: You are able to add up to five images associated with your item.

- Button Labels: You can choose optionally to label your buttons, choosing between available text options such as “PayPal”, “Buy Now”, or “Checkout”.

- Customer Note: Tell customers what details you need like “Delivery Instructions.” You can even require customers to enter a note.

- Product ID: Include your product identifiers or SKU numbers.

- Variants: Let customers know if your product or service is available in up to 3 variations like color, size, type, etc. (You are able to adjust price per variant.)

- Inventory: This lets PayPal keep track of your items and variants.

When you click the Checkout tab, there are additional fields.

- Shipping Address: Enable to collect shipping address at checkout.

- Shipping Fees: Enable to set shipping fee for this item, including free shipping.

- Taxes: Enable to set the tax rate for this item.

Finally, on the Confirmation tab, you have one option.

- Auto-return URL: Choose a URL to let customers automatically return to your site after checkout.

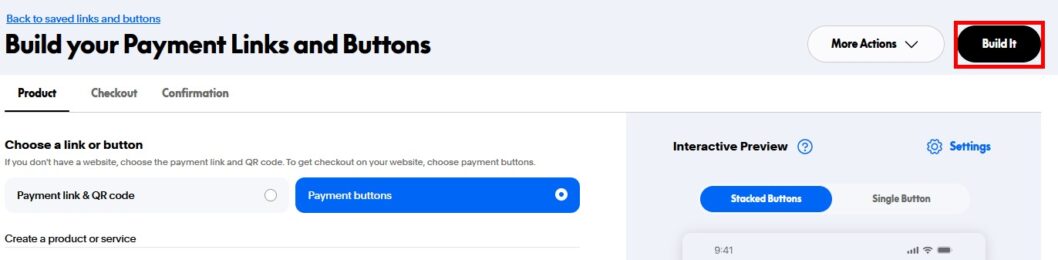

8. Click Build It.

Once you have configured all button options to your satisfaction, click on Build It to generate the code you will insert on your website.

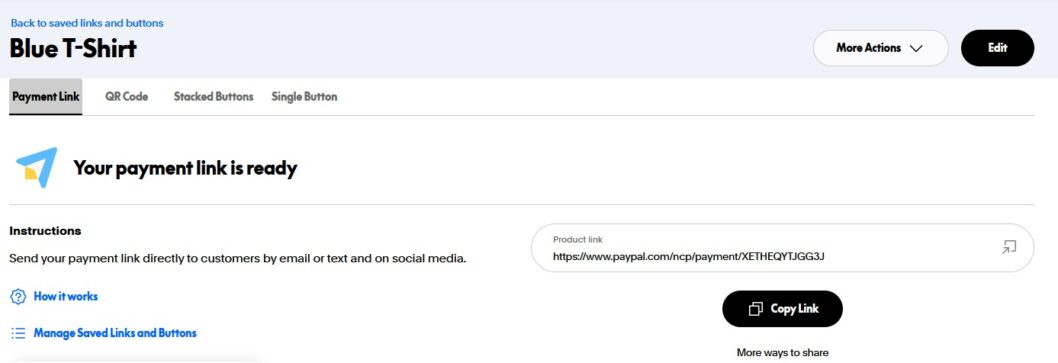

9. Add the button to your website.

When you’re done, you will have the ability to add the button to your website in a few ways:

- Payment Link: Simply copy and paste the payment link and send by email, text, or social media.

- QR Code: Gives customers a scannable link that will take them to your payment page.

- Stacked Buttons: Copy the HTML or React snippet and paste to your website. (Shows multiple buttons including “PayPal” and “Checkout”).

- Single Button: Copy the HTML or React snippet and paste to your website. (Shows just one checkout button).

Final Thoughts

There you go! Adding a PayPal button to your website is one of the fastest ways to start selling items online.

Remember: if you need help storing and shipping items once they start selling, Fulfillrite can help. We provide order fulfillment for businesses like yours. You can request a quote to learn more.

Navigating the complex world of subscription box order fulfillment may seem overwhelming. But with the right strategies and tools, order fulfillment processes can quickly become a subscription box business owner’s best friend.

Adopting advanced technology, streamlining your processes, fostering strong supply chain relationships, preparing for scalability, and keeping a pulse on emerging trends can turn fulfillment from a challenge into a competitive advantage.

Remember, a successful fulfillment process is more than just sending boxes—it’s about crafting a unique, satisfying customer experience that drives loyalty and growth. Your patrons aren’t just buying a box; they’re investing in a promise you make every month.

Let’s ensure you deliver on that promise perfectly every time.

Why Order Fulfillment is So Important in the Subscription Box Business

Order fulfillment is the heartbeat of any subscription box business. It is the series of steps that bridges the gap between a customer placing an order and receiving their curated box of goodies right at their doorstep. The process begins with managing inventory and extends through packaging, shipping, and delivery of the subscription boxes.

Fulfillment plays a vital role in shaping your customers’ experiences and, by extension, their loyalty to your subscription box service. A well-executed fulfillment process ensures that the orders are accurately packed, labeled, and promptly delivered.

In a business model that relies heavily on customer retention, your patrons will come to appreciate and expect the seamless service your business offers with each delivery. After all, remember that 87% of customers “are highly likely to shop again with an online store after a positive delivery experience.” Therefore, an effective fulfillment process significantly contributes to customer satisfaction and repeat business.

However, the importance of order fulfillment isn’t limited to creating positive experiences. It’s equally crucial in preventing negative ones. For example, 69% of consumers are “less likely to shop with your business if you fail to meet your delivery window.”

Mishaps in the fulfillment process, such as incorrect items, late deliveries, or damaged goods, can quickly tarnish your brand’s reputation. In addition, in today’s digitally connected age, customers are likely to share their dissatisfaction online, which can discourage potential subscribers. In the worst-case scenario, a poorly managed fulfillment process can lead to a high churn rate, impacting revenue and growth.

In a nutshell, the order fulfillment process isn’t just about getting boxes from point A to point B. It is about crafting a positive experience that encourages your customers to maintain their subscriptions and promotes the growth of your business. Doing it right can transform a one-time buyer into a long-term, loyal subscriber and, ultimately, become a key competitive advantage for your subscription box business.

Why Order Fulfillment is So HARD in the Subscription Box Business

The subscription box business is unique in its nature, and as such, it presents its own unique set of challenges in the realm of order fulfillment.

First off, customization complexities. A significant allure of subscription boxes is their personal touch, their ability to deliver surprises catered specifically to the customer’s tastes. However, this tailored experience means each box is unique, making the fulfillment process more intricate. It must cater to various preferences, sizes, and themes, complicating packing and inventory management.

Next, we encounter considerable swings in order volume at any given time. Some subscription boxes go out at certain times of the month, for example. Building routines and standard procedures around this feast-or-famine demand volume can be difficult.

Thirdly, inventory management. Predicting stock levels becomes a fine art with varying customer preferences and changing trends. You want to avoid being left with excess stock or a shortage that could lead to disappointed customers. Balancing this tightrope is no easy feat.

Then there are the more common logistical hurdles found in any eCommerce business. Delivery accuracy and speed are vital in any e-commerce business, and subscription boxes are no different. Ensuring that each unique box reaches the right customer in the right place and time is a significant challenge.

On top of all this, there are the unique struggles of scaling up. As your business grows, so do your challenges. More customers mean more boxes, deliveries, and opportunities for things to go wrong. Maintaining the same level of quality and efficiency during expansion can be a herculean task.

How To Handle Order Fulfillment For Your Subscription Box Business

Understanding and overcoming these challenges might seem intimidating. However, proven strategies and tools can make order fulfillment more manageable and efficient for your subscription box business.

1. Use the latest technology for inventory management and order tracking.

Adopting advanced technological tools can make navigating the complexities of a subscription box business significantly easier. This is particularly true when managing inventory and tracking orders—two core components of your operation.

Consider utilizing cloud-based inventory management systems such as Zoho Inventory or Quickbooks Commerce. These platforms provide real-time updates on stock levels, track the movement of items across various locations, and even manage reordering processes. They use powerful analytics to anticipate future stock needs based on past patterns, helping to prevent overstocking or understocking issues that could impact your bottom line and customer satisfaction.

Order tracking is another area that benefits immensely from technological advancements. Tools like ShipStation or EasyShip offer end-to-end tracking solutions that update you on the whereabouts of your shipments and provide your customers with real-time delivery updates. This level of transparency can significantly improve the customer experience, allowing your subscribers to anticipate when they will receive their curated boxes.

In terms of automation, even simple technologies such as address validation can reduce the risk of human error. This results in fewer misdirected shipments, greater profit margins, and more time to spend on strategic initiatives that drive business growth.

2. Streamline processes for maximum efficiency.

Efficiency is the key to successful fulfillment operations, and streamlining your processes can significantly enhance this. Here’s how you can achieve it in your subscription box business.

Start by conducting a thorough analysis of your current processes. Tools like process flowcharts can help visualize every step, from inventory management to box delivery, and identify potential bottlenecks or wasteful activities.

Next, implement standard operating procedures (SOPs) for repetitive tasks such as box assembly and labeling. For instance, adopting an assembly line approach—where each team member is responsible for a specific task—can improve speed and reduce errors.

Finally, embrace the principle of continuous improvement. Regularly review your processes and make data-driven decisions for incremental enhancements. For example, if a particular supplier consistently causes delivery delays, it might be time to consider alternatives.

Remember, a streamlined operation results in faster delivery times, fewer errors, and higher customer satisfaction.

3. Foster relationships in the supply chain industry.

Building strong relationships within your supply chain is critical to the smooth operation of your subscription box business. These relationships encompass your suppliers, logistics providers, and even your delivery personnel.

With suppliers, open communication and mutual trust are paramount. Regularly share updates about your business, growth plans, and challenges. For example, if you anticipate a spike in demand during the holiday season, notifying your suppliers in advance can ensure they’re prepared to meet your increased needs.

Also, consider partnering with logistics providers who specialize in subscription box services. Companies such as Fulfillrite are familiar with the unique needs of this business model and can offer invaluable support and expertise.

4. Prepare for scalability.

As your subscription box business expands, it’s vital to prepare your fulfillment operations for scalability. Anticipating future needs can ensure a smooth transition during periods of rapid growth.

Consider your storage needs. As your customer base grows, you may need to hold more inventory. If you choose to manage orders on your own, warehouse management systems like Logiwa can help optimize your warehouse space and track inventory across multiple locations.

As your operations expand, consider outsourcing fulfillment to a third-party logistics provider (3PL). By their nature, 3PLs specialize in handling increased order volumes, freeing up your time to focus on core business strategies.

Finally, regularly revisit your scalability plan. As your business evolves, so should your strategies to ensure continuous growth and success.

5. Be aware of emerging trends and technologies in fulfillment.

Staying abreast of emerging trends and technologies in fulfillment can give your subscription box business a competitive edge. You may want to select a fulfillment partner with a forward-thinking philosophy toward implementing new technology.

Regardless of whether you ship on your own or with a partner, though, here are a few promising technologies to watch out for:

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing inventory management and demand forecasting. AI-driven tools like EazyStock can predict future inventory needs based on past data and patterns, helping you avoid overstocking or stockouts.

Automation in warehousing, including the use of robots for picking and packing, can increase efficiency and accuracy. Companies like Amazon are already leveraging this technology.

Drones and autonomous vehicles for delivery are gaining momentum. Though not widespread yet, keeping an eye on this trend could position your business ahead when it becomes mainstream.

Blockchain technology, despite its primary association with cryptocurrency, can also be used for tracking shipments in a way that improves transparency and security in the supply chain. For instance, IBM’s Food Trust uses blockchain to track food products from farm to consumer.

Invest time in understanding these trends and consider their potential benefits for your business. Being an early adopter could pay dividends in the long run.

Final Thoughts

Successfully managing order fulfillment for your subscription box business is complex. It involves juggling customization intricacies, dealing with order volume surges, optimizing inventory, overcoming logistics hurdles, and preparing for scalability. However, with the right strategies in place and by harnessing the power of the latest technology, these challenges can transform into opportunities for growth.

Streamlining your processes, fostering strong supply chain relationships, planning for scalability, and staying ahead of emerging trends can significantly enhance your fulfillment operations. Remember, at the heart of it all, your goal is consistently providing an excellent customer experience. Ultimately, this will drive customer loyalty, foster retention, and contribute to your business’s long-term success.

FAQ

Should I handle fulfillment in-house or outsource to a 3PL?

Start in-house if you’re shipping fewer than 500 boxes per month and have adequate storage space. Beyond that volume, consider a 3PL specializing in subscription boxes. They understand the unique challenges of customization, irregular shipping schedules, and seasonal spikes that subscription businesses face.

How do I handle inventory for seasonal or limited-edition items?

Use demand forecasting tools based on historical data and subscriber preferences. For limited editions, consider pre-orders or waitlists to gauge demand. Always maintain a small buffer stock for popular items, but avoid overordering seasonal products that may become obsolete.

What’s the best way to manage customization at scale?

Implement customer preference profiles in your system and use automated picking software that can handle multiple SKU combinations per order. Some 3PLs offer kitting services where they pre-assemble customized combinations based on subscriber data you provide.

How can I reduce shipping costs for subscription boxes?

Negotiate volume discounts with carriers, optimize box sizes to reduce dimensional weight charges, and consider regional fulfillment centers to reduce shipping distances. Some subscription businesses also offer shipping upgrades as paid add-ons to offset premium delivery costs.

What happens when subscribers change their address mid-cycle?

Implement address change cutoff dates (typically 3-5 days before shipping) and clearly communicate these to subscribers. Use address validation software to catch errors early and maintain updated subscriber databases with automated sync between your subscription platform and fulfillment system.

How do I handle damaged or missing items in subscription boxes?

Establish clear policies for replacements and refunds. Track damage rates by carrier and packaging type to identify improvement opportunities. Many subscription businesses maintain emergency inventory specifically for replacements to avoid disappointing long-term subscribers.

Want to get organic traffic to your store so you can make some sales? Ecommerce search engine optimization, or SEO, is how you do that.

Optimizing your website for search engines will help increase visibility, attract potential customers, and improve your chances of turning those visitors into buyers.

SEO can be broken down into a bunch of smaller disciplines. There’s technical SEO, which is about your site’s speed, structure, and security. Then there’s on-page SEO which is focused on making individual pages more searchable. Then there is content marketing and link building, which is about making pages people want to read and then getting those pages in front of readers.

It’s a lot to take in, especially if you don’t have a technical background. It’s for that reason that we compiled this guide to give you some actionable tips to help you get started.

So let’s begin with a quick definition of eCommerce SEO.

What is Ecommerce SEO?

Ecommerce SEO is all about optimizing your online store to rank higher in search engine results. Unlike general SEO, eCommerce SEO zeroes in on product and category pages, optimizing for relevant keywords, and enhancing the user experience to turn visitors into customers. It targets specific search terms to attract shoppers actively looking for the products you sell.

Good SEO impacts your store’s visibility, making it easier for customers to find your products. High search rankings lead to increased organic traffic and better conversion rates. Effective SEO strategies also boost your online presence, helping you attract and retain customers, which ultimately drives sales and growth.

In this guide, we’ll provide tips on how exactly you can optimize for SEO.

Technical SEO Tips

Optimizing the technical aspects of your site is crucial for better search engine rankings. But technical SEO can get complex if you research it online.

To help you get started, here are some concrete steps to help you optimize your technical ESO.

#1: Optimize your site structure.

A well-organized site structure is a must for SEO. As Nikola Baldikov, CEO of Inbound Blogging, suggests, “start with defining your categories. They should be logical and intuitive, so both users and search engines can browse the website easily.”

He continues, saying, that “if you don’t know where to start, try checking what your competitors are doing and gathering some ideas. Simply uploading products without considering the organization can cause your visitors to get confused and hurt your sales.”

#2: Make sure your website is mobile-friendly.

Mobile optimization is key since search engines prioritize mobile-friendly sites. After all, 45% of web users shop through their phones.

Brandon Schroth, Founder at Reporter Outreach, emphasizes that “mobile phones are the most popular form of devices used to perform online shopping.” He goes on to say that “if a website is not mobile optimized, user experiences may be imperiled, in addition to search rankings being affected.”

Make sure your site is responsive and adapts to different screen sizes. This is because a mobile-friendly site enhances user experience, reduces bounce rates, and boosts search performance. Or, put in a less technical way, people stay on your site for longer and are more likely to buy.

#3: Improve site speed.

Fast-loading websites rank higher and offer a better user experience. “Speed matters more than you think,” says Nathaniel Miller at The SEO Marketing Dad. “Make sure your site loads fast and looks great on mobile. Customers expect quick, seamless experiences, and Google rewards it too.”

If you want to improve your site’s load time, then optimize images, turn on browser caching, and minimize HTTP requests to improve loading times. Use tools like GTMetrix to find and fix speed issues.

#4: Secure your site with HTTPS.

Security is a ranking factor, and HTTPS ensures that data exchanged between your site and users is encrypted. Make sure you have a valid SSL certificate to secure your site. Additionally, HTTPS improves user trust and can lead to better search engine rankings, as search engines prefer secure sites.

If you have trouble doing this, use Why No Padlock to troubleshoot.

On-Page SEO Strategies

On-page SEO is all about optimizing individual web pages to rank higher and attract more relevant traffic from search engines. Here are some specific tips you can apply today to improve your on-page SEO.

#5: Optimize product pages with targeted keywords.

Make sure to incorporate relevant keywords naturally in your product titles and descriptions. Use keywords that your potential customers are likely to search for. Be sure to also include them in headings, subheadings, and bullet points. This helps search engines understand your content and rank your pages higher for those specific terms.

But that said, avoid the temptation to stuff keywords into product titles and descriptions. You instead want to incorporate relevant keywords naturally. Tom Jauncey of Nautilus Marketing advises that you “optimize product pages with unique, keyword-rich descriptions and high-quality images. Too many eCommerce sites rely on manufacturer descriptions, which can hurt rankings. Make sure each product page offers value in terms of content.”

#6: Use high-quality images and optimize alt text.

“The first SEO tip for an eCommerce site is image optimization,” says SEO consultant, Jase Rodley. “Since eCommerce is all about visuals, make sure all product images are high quality and have descriptive alt text with relevant keywords. This helps with SEO and accessibility.” He also recommends using user-generated content like customer reviews and testimonials, which he says, “adds fresh unique content to your product pages and builds trust with potential buyers.”

#7: Create compelling meta descriptions.

Meta descriptions are short descriptions of your page that can be sent to search engines. Usually, they are 160 characters at most.

You need to write concise and compelling meta descriptions for each page. This will involve summarizing the page content and including targeted keywords.

Now you should know – meta descriptions not always appear in search results. It depends on the search terms used and, frankly, whether or not Google feels like using your meta descriptions.

But all the same, well-written meta descriptions increase the odds that searchers turn into visitors.

#8: Optimize URL structures for clarity and keywords.

Create clear, concise URLs with relevant keywords. Avoid long, complex URLs. Google, and other search engines, tend to dislike long URLs or ones that contain irrelevant information like random numbers.

Additionally, as Ross Kernez from SEO Meetup suggests, building links from trustworthy websites in your industry can further enhance your site’s rankings by signaling credibility and relevance to search engines. “Aim to get links from well-known, trustworthy websites in your industry,” says Kernez. “These good links help boost your site’s ranking in search engines.”

Content Marketing for SEO

Creating valuable content is a good way to improve your search rankings. Sometimes, this means improving the quality of your product pages with reviews or FAQs. Other times, it means creating blog posts, videos, and other forms of content to help answer questions that your customers may have.

No matter how you choose to go about it, content marketing is a proven way to help boost your SEO.

#9: Start a blog related to your niche.

It’s not relevant for every niche, but it works like a charm when it is! Regular blog posts can improve your search rankings and also help you establish your site as an authority in your industry.

Blogging allows you to create keyword-rich content that attracts organic traffic. In order to do this, write about topics relevant to your niche, addressing common questions and sharing useful knowledge.

#10: Use user-generated content.

Encourage customers to leave reviews and testimonials on your site. User-generated content (UGC) adds credibility and naturally incorporates relevant keywords.

“Feedback and reviews from your existing customers offers social proof and helps to convince and convert new customers,” says Michelle Symonds, CEO of Ditto Digital.

It’s not hard to understand why search engines like UGC. Much like human beings, search engine bots like seeing proof that your brand is as good as you say it is!

Positive reviews can also improve your search rankings and attract more visitors by showing that you have satisfied customers.

Building up UGC takes time. But one way you can speed up the process is by remembering to ask customers to leave reviews. Many will if you remember to ask!

#11: Build a keyword-rich FAQ page.

Create an FAQ page that addresses common questions and concerns related to your products. As you answer questions, you will naturally use keywords in the questions and answers.

“I would recommend that sites prioritize their product descriptions,” says Kim Butler from Online Optimism, “being sure to answer any potential questions their customers might ask. You could also include this in frequently asked questions after descriptions to add more value.”

In addition to being good for SEO, adding FAQs improves user experience, on top of simply driving organic traffic to your site.

Link Building Techniques

Search engines tend to favor websites that other sites link to. When other sites link to your website, these are called backlinks. The more high-quality backlinks you have, the better your website will rank.

So here are some tips on how you can build up your backlinks.

#12: Implement a link-building strategy.

“Link building, [such as] building links to the root of your domain via brand mentions, is not only important but is one of the most natural ways to obtain backlinks over time,” says John White from Complete White Label. “I recommend doing this via expert commentary campaigns.”

That’s just one technique you can employ though, as there are a lot of ways you can get backlinks. Many of them boil down to networking.

To acquire quality backlinks, reach out to the owners of larger sites. Offer to create guest blog posts or strike up a partnership. A lot of this will come down to outreach, often cold outreach, done via email or social media.

Another good way to build up your link profile is by getting mentioned in the media. You may also consider using websites like Qwoted or HARO to get in touch with reporters.

#13: Partner with influencers for content outreach.

Collaborate with influencers to create and share content that includes links to your site. Influencers can reach a wider audience and provide high-quality backlinks. This not only improves your link equity but also drives targeted traffic.

“Apart from increasing your credibility,” says Brandon Schroth from Reporter Outreach, “this will also help expand your brand’s reach. Moreover, these collaborations help in producing creative and original content that can be published on social networks and other digital media, thus generating quality backlinks and increasing the visibility of your website.”

Overall, this is a smart way to increase brand awareness. This is especially true in some niche markets such as cosmetics.

It’s also useful to remember that influencers aren’t just people with big Instagram or TikTok followings. Reporters, reviewers, bloggers, and even community organizers are all influencers in the broader sense of the term. Don’t overlook them because of all the people talking into ring lights!

#14: Use internal linking wisely.

“Don’t skip out on the importance of internal linking,” advises Nathaniel Miller from The SEO Marketing Dad. “Internal linking is a powerful way to guide users and spread link equity. Don’t overlook it.”

Internal linking helps distribute page authority throughout your site and improves navigation. Link related products, blog posts, and category pages to enhance user experience and SEO. Be sure your most important pages receive the most internal links.

You will also want to make sure you use descriptive anchor text. That means avoiding turning words like “here” into links. The linked text itself needs to tell you something about the page that is being linked to.

Advanced SEO Tips

SEO advice can become very complex. If you follow all of the previous tips but are still looking for further ways to improve, here are a few more things you can do.

#15: Use schema markup for rich snippets.

Schema markup helps search engines understand your content. When you use schema markup, it can improve search result visibility with rich snippets.

Rich snippets include additional information below the meta description in the search result. That might include a product rating, number of reviews, price, delivery cost, returns policy, and similar information.

Paul DeMott, CTO at Helium SEO, explains that using it for “highlights like stock, ratings, and pricing can boost your presence on search engine result pages by offering rich snippets.”

In order to add rich snippets, you need to implement schema markup. This can get complex, so here is a guide on how you can do this in Shopify.

While complex, it is often worth it. That’s because rich snippets improve click-through rates by making your listings more attractive.

#16: Optimize for voice search.

Voice search is becoming more common. So think about the kinds of keywords people will use when using Siri for search.

Think about how you can get your pages to rank when using natural spoken language. Think about the kind of long-tail keywords that reflect how people speak.

Truthfully, this is very hard to do. But if you answer common questions directly in your content, such as descriptions, you will improve your odds of appearing in the voice search results. This is because of the conversational nature of copywritten text online.

For more information, check out this post by Design Rush on voice search best practices.

#17: Focus on local SEO if applicable.

You might also consider optimizing your eCommerce site for local search if you have a physical store or target a specific region. Include your business address, phone number, and operating hours on your site. Use local keywords.

If nothing else, create a Google My Business listing to improve your visibility in local search results.

#18: Use comparison pages.

“Comparison pages targeting keywords like ‘Product A vs. Product B,’ are perfect for capturing bottom-of-funnel shoppers who are ready to buy but need that final push,” says John Butterworth of Mint SEO.

“They’re searching for specific product comparisons, so give them a clear breakdown of features, benefits, and pricing to help them decide. If your page has a clear winner, it’s likely the customer will purchase that product straight after reading.”

#19: Make gift guides for seasonal SEO.

Another underrated tip, advocated for by Hemapriya Natesan is creating seasonal guides. She says that you can “create blogs centered around popular themes, like holiday gift guides, that incorporate long-tail keywords.”

On those pages, you can “showcase your products with high-quality images, customer experiences, and descriptions that illustrate why they’d make thoughtful gifts.”

It should be noted this can be a solid way to acquire first-time customers since shoppers tend to be more open to new brands during the holidays.

Final Thoughts

When it comes to SEO, there is one animating principle. Make a site that people want to find!

In practice, that means creating a site that is easy to use, secure, and loads quickly. That’s where technical SEO comes in. Every single page needs to be useful, which is where on-page SEO is handy.

The best sites make content that users want to find and distribute it to other websites where it can be found. To accomplish that, you need content marketing and link-building.

Take a few of these tips and think about how you can apply them to your site. There’s a good chance that they’ll help you improve your eCommerce SEO game!

Further Resources

For further learning and implementation of advanced SEO techniques, consider the following tools and resources:

- Google Search Console: Monitor and maintain your site’s presence in Google search results.

- Ahrefs: Comprehensive SEO toolset for keyword research, backlink analysis, and site audits.

- Moz: Offers tools and resources for SEO learning, including keyword explorer and link-building strategies.

- SEMRush: An all-in-one marketing toolkit for SEO, including competitive analysis and site audits.

- Yoast SEO: A popular WordPress plugin to optimize on-page SEO.

- Neil Patel’s Blog: Extensive resources and guides on SEO best practices and strategies.

FAQ

How long does it take to see results from eCommerce SEO?

SEO is a long-term strategy. You might see some improvements in 3-6 months, but significant results typically take 6-12 months or longer. Technical fixes like site speed improvements can show faster results, while content marketing and link building take more time to compound.

Should I hire an SEO agency or do it myself?

It depends on your budget, time, and technical comfort level. If you’re just starting out, focus on the basics yourself—technical SEO, product page optimization, and creating quality content. As your business grows, consider hiring professionals for more advanced strategies like link building and technical audits.

How do I choose the right keywords for my products?

Start with how your customers actually search. Use tools like Google’s Keyword Planner or Answer The Public to find relevant terms. Focus on a mix of high-volume competitive keywords and longer, more specific phrases that your ideal customers might use. Don’t ignore local keywords if you serve specific geographic areas.

Is it worth optimizing for voice search?

Voice search optimization is becoming increasingly important, especially for mobile users. Focus on natural, conversational language in your content and FAQ sections. Answer questions directly and concisely, as voice assistants often read featured snippets aloud.

How many keywords should I target per page?

Focus on one primary keyword per page, with 2-3 related secondary keywords. Avoid keyword stuffing—search engines prefer natural, helpful content over pages crammed with keywords. Your primary keyword should appear in the title, URL, and naturally throughout the content.

Do I need to optimize every single product page?

Yes, every product page should have unique, optimized content. Avoid using manufacturer descriptions across multiple products. Each page should have unique titles, descriptions, and relevant keywords while maintaining helpful, readable content for your customers.

Shoppers are impatient. Every additional tenth of a second it takes a store to load can drop conversion rates by 7%. Can you imagine how much money a Shopify store owner could lose over a 2-second delay?

Slow websites provide bad user experiences. This alone causes people to turn away from stores they would otherwise shop from. But it can also negatively impact search engine rankings too. That’s another huge problem in its own right since so many Shopify store owners count on being listed high in Google Shopping ratings.

Fixing a slow website is tricky and technical. But thankfully, it’s easier to troubleshoot issues on Shopify than it is on most platforms. In this guide, we’re going to talk about what makes Shopify stores load slowly and why it matters (in the words of actual store owners).

We’ll wrap up with clear steps you can follow to troubleshoot your slow store.

Why Your Shopify Store Is Loading Slowly: 3 Common Reasons

Shopify stores can load slowly for a lot of reasons — oversized images, sluggish apps, theme issues, you name it. We’re going to talk about each of these in a little more detail so you can understand why each one of these causes loading issues.

This is not an exhaustive list. Truth is, there are a million reasons why your Shopify store could be loading slowly. You might have a server issue or some kind of obscure coding problem. But 95% of the time, something much simpler is giving you trouble.

Here are three loading time issues that come up all the time and that you are going to have some control over.

1. Your images are too big.

Big images are, by far, the most commonly cited reason why Shopify stores load slowly. Nearly every source we asked for advice on this matter told us this, independently of one another.

Jose Gomez, Partner at Summit Metals, put it best. “Websites generally load slowly because images are not optimized in size. For example, people might upload a JPG that is 3MB.”

On its own, that isn’t a problem, but clarifies, saying that “multiplied by 20 images, your cell phone will take a while to load [the web page].”

There are ways you can troubleshoot this, which we’ll get into more later. Gomez recommends converting images to WEBP format, which cuts size by about 70% without sacrificing quality too much. Meanwhile, Steve Sacona, Founder of Top 10 Lawyers, recommends using tools like Photoshop or free online converters to compress images to smaller sizes. In our experience, we’ve found either technique can work well.

2. One or more of your apps is slowing down your site.

Remember the days when iPhones only had 8 or 16 GB of storage? Take a second and rewind to the days of having to delete apps to make room for your music. Shopify works like that.

If your store has app after app that you are not using, it might be slowing the site down. Consider purging unneeded apps and reap the benefits of faster load times.

“Carefully choose the apps that you add to your store, and remove any that aren’t needed,” suggests Justin Christopher, Manager of Ecommerce and Marketing at Klatch Coffee. “In addition to removing the app, you might need to check to make sure the app automatically removes any code that it installed, because old apps can leave behind code that slows your site. Shopify store owners can run before-and-after tests using Google Lighthouse to ensure that newly-added apps aren’t slowing their store.”

3. You’re using a slow Shopify theme.

When themes don’t work properly, they can slow down your page. Themes are all made by developers, and developers make them by writing code. The way the code is written can have a huge impact on how the website itself is loaded when it runs that code.

Practically speaking, if your theme is the problem, the only option you really have is to switch themes. Granted, there are many other things you can troubleshoot first, which we’ll talk about. But if you keep having stubborn performance issues, your theme might be the problem after all.

Why Shopify Store Loading Time Matters

If you want to really understand why loading time matters so much, it helps to hear what other store owners have to say.

Gomez says that “Google/Bing Search Engine crawlers rate your site based on how fast your site runs. The reason for this is they want to give users best user experience (which means smooth loading times.”

Christopher states that “site speed is critical for usability. We know that visitors quickly abandon slow-loading websites, especially mobile users, which make up about 70% of our audience.” He then expressed the value of using Lighthouse, Core Web Vitals, and Search Console to find and fix issues.

“There is a reason loading time is important for many reasons. Ignoring this essential aspect can scare away prospective buyers, because an average online shopper is quite impatient, and every additional second of waiting increases the bounce rate and decreases the satisfaction rate,” says Ben Schreiber, Head of Ecommerce at Latico Leathers. “Even a [one-second] delay can lead to fewer conversions, according to research. SEO is also adversely affected by slow websites as search engines such as that of Google take loading speed as a factor when indexing web content. Reduced download times mean enhanced popularity and increased chances of converting visitors into regular clients.”

Sacona states that “fast loading times are essential for keeping visitors on your site and can directly impact your business’s bottom line. From a legal standpoint ᅳ seeing to it that your website performs efficiently is not just about user experience ᅳ it’s about seeing to it that your business against potential disputes & maintaining your market position.”

Taken all together, one thing is clear. Making your Shopify store fast is not just an intellectual exercise. It has a direct impact on your profitability.

How To Speed Up Your Shopify Store: 7 Steps

With all of the above in mind, we would like to provide some tips on how you can speed up your Shopify store. Try each of these steps one at a time, and in the order they are listed below. Use free tools like GTMetrix, Pingdom, and PageSpeed Insights to measure changes in performance as you go along.

Why follow these specific steps?

This is a technical point, but it’s helpful to understand, so bear with us. You are trying to optimize three different factors:

- Largest Contentful Paint (LCP): The amount of time it takes to load the largest object on the page. Less time is better.

- Interaction with Next Paint (INP): The amount of time it takes for a website to respond after a user interacts, such as by clicking on something. Less time is better.

- Cumulative Layout Shift (CLS): The amount that objects appear to “jump around” as the website loads. Less shifting is better.

The tips that we’re going to share require relatively little technical expertise but should make a large impact on these three figures. Don’t get too hung up on the figures themselves, though, they are ultimately just ways to quantify how it feels to use your website. And you want it to feel good, so use your human judgment.

1. Optimize your images.

If your website is loading slow, you should check your images first. That’s because overly large image files are both the most likely reason for your website to be loading slowly and one of the easiest to fix.

There are two ways main ways to optimize images, and either will work. You can either convert them to WEBP or use a tool – paid or free – to compress the images to a smaller file size. It doesn’t matter which one you use, it only matters that the file size is relatively small.

Of the two, we personally find WEBP preferable since it’s a little less technical than compressing images and certain speed measurement tools tend to like it better than optimized PNG and JPG files.

When you compress images, look at them closely and make sure the quality is still good before you use them on your website. You want the smallest file that still looks good.

Windy Pierre, Ecommerce Growth Marketer at Ecommerce Manager Dot Com has some additional recommendations for image optimization. He says it’s best to “[avoid making] the main picture load lazily. Only make pictures that you can’t see right away [should] load lazily. For more control, it’s better to use Shopify’s automatic lazy loading or the section index.”

He also advises against using special effects for main pictures. “While making pictures fade in might seem cool, it can make the website slower. It’s better to remove them for a faster website.”

2. Remove apps you don’t use.

Having too many apps is a sure way to slow down your Shopify store. The easiest thing you can do is start removing ones you don’t use.

Sacona is a fan of this approach, saying that a “quick fix is cutting back on unnecessary plugins and streamlining your site’s design to reduce the number of elements that need to load.” Removing extra apps is a great way to do this and requires relatively little explanation.

3. Eliminate pop-ups and lightboxes.

You likely want to avoid removing apps that you use on a regular basis. But if you’ve optimized your images and removed unnecessary apps, and you’re still running into load time issues, you might need to consider removing some marketing-related apps. Of those, the easiest thing to check for are slow-loading pop-ups and lightboxes.

“Don’t use big pop-ups. Pop-ups for cookie consent and signing up for newsletters can take a long time to load and be the most significant thing on the page,” says Pierre. If you use them, he advises that you “make sure the text or pictures in these pop-ups are small.”

4. Disable apps one by one.

If you are still having problems with loading time after optimizing images, removing old apps, and turning off pop-ups and lightboxes, you need to go a bit further. At this point, we recommend that you start disabling apps one by one and seeing how each removal affects performance. Odds are, you’ll find at least one app is tanking your load time and it’s only by disabling them one by one that you’ll be sure which one it is.

5. Toggle your lazy loader settings.

Lazy loaders cause images to load only when they are needed. For the most part, lazy loading helps a lot with site performance and Shopify’s Dawn theme enables it by default.

But sometimes, lazy loading has problems and you need to turn it off or on. This can get a bit technical, so here is a video that can walk you through the process of enabling and disabling lazy loading. It’s best to try both ways and see which one gets a better performance.

6. Make sure your CDN is working properly.

CDN is short for content delivery network. CDNs basically save a copy of your website’s files in various servers all over the world. When people load your website, the files come to them from servers that are located physically closer to them. That means the actual electronic information that moves in physical form through fiber optic cables doesn’t have to go as far.

This is nice, since Shopify’s development team has not figured out how to move data faster than the speed of light. Give them a couple of years, though, and we’re sure they’ll figure it out!

If you use Shopify to host your store, you are automatically using their CDN. For the most part, Shopify’s CDN is excellent and probably won’t give you any trouble. But if you can’t quite get the performance you need, here is a tutorial that will walk you through replacing the default CDN with one of your choosing.

7. Use a fast Shopify theme.

If you have followed the above steps and you are still running into issues, it’s possible that your theme is slowing down your website. We saved this tip for last because switching Shopify themes requires a lot of extra work and it’s not something you want to do lightly.

But if you do get to this point, Justin Christopher recommends that you “choose a theme for your Shopify store that makes fast loading a priority, and comes from a reputable developer. Quality themes include regular updates that include bug fixes and new features, as well as performance improvements.”

Bonus Tip: Don’t Forget About User Experience

This article has focused on technical fixes, and those are important. But don’t forget about things like ease of navigation and checkout. This dramatically affects perceived speed of the website, whether or not it loads in 300 milliseconds or not.

“One of the easiest wins to improve your conversion to check out process is to simplify the checkout experience for the user,” says Dan Korte of Riseabove Apparel. “I can not think of any more effective way to remove friction from your checkout experience, than offering a guest check-out setting with a streamlined check-out, and talented graphic presentation.”

That is to say, don’t forget to test how your site feels to use while you’re testing how long it takes to load.

Final Thoughts

A slow Shopify store doesn’t just frustrate customers—it costs you money. Every second of delay means fewer conversions and lower sales. If your store isn’t loading fast enough, you’re essentially turning away shoppers who are ready to buy.

Speed matters. It affects user experience, search engine rankings, and ultimately, your bottom line. With so many factors influencing loading times, you can’t afford to ignore the problem. Start with the basics: optimize images, remove unused apps, and choose a theme designed for performance.

Fixing a slow store takes effort, but it’s worth it. Follow these steps, track your progress, and watch your store’s performance improve. A faster site leads to happier customers and a more profitable business.

Scaling your eCommerce store is no small feat—and who better to guide the way than those who’ve done it themselves? We reached out to a variety of experienced eCommerce experts to find the strategies that work in the real world.

In this article, we share their insights, drawn from real-world experience. Then we turn their thoughts into clear steps you can follow so you can scale efficiently and sustainably.

This guide covers everything from streamlining operations to fostering long-term customer loyalty. Along the way, we’ll also talk about important metrics you can watch so you can make smarter decisions.

Whether you’re trying to optimize a successful business or grow your brand into something much bigger, this advice can help you as you grow.

How do I make eCommerce scalable?

Scaling an eCommerce store means you have to think like a civil engineer. Let’s say you’re building a skyscraper. You know that if the foundation isn’t rock-solid, everything is going to end up being unstable under the weight of every extra pound of girders and beams.

That means your goal is to create systems that grow with your business. That means streamlined operations, efficient logistics, and scalable technology.

Try to scale without these, and you’ll find that scaling just means multiplying problems. Efficiency is the name of the game.

Below are specific steps to make eCommerce scalable, broken down into actionable tips.

1. Tighten your backend systems.

Matthew Engelage, founder of Chin Mounts, emphasizes that “scaling a broken system just increases frustration.” Your inventory management, shipping processes, and customer support need to operate seamlessly. Without these foundations, every new order risks becoming a headache. He also warns to “keep an eye on your margins. Growing quickly doesn’t mean much if you’re not profitable.”

Tip: Either use software or make better use of existing software to manage your inventory and order fulfillment. The less manual work involved, the more room you have to grow.

2. Find your bottlenecks.

“Scaling effectively is all about efficiency,” says David Taylor, founder of Academized.com. Take time to analyze where your business slows down. Is your team underperforming? Is your customer acquisition cost (CAC) unsustainable?

Put another way, you need to focus on “solving the right problem in the right way,” to borrow words from Olivia Tapper, Co-founder & COO of PetPortraits.com.

Or if you prefer this put even more starkly, Michael Alexander, Managing Director of Tangible Digital says that “I have noticed that the largest mistake made by companies when scaling is to get lost between momentum and a real progress. Growth is very exciting initially, but when the processes involved in it might not be able to maintain the pace, the situation collapses. Not scaled is not growth, but merely a weakness preparing to manifest itself. Authentic success must be anchored on the ground that will be in a position to handle the existing wins, not to mention the battles of tomorrow.”

“Excessive growth and scaling on a thin margin regularly ruins the cash flow,” warns Paul Ferrara, Senior Wealth Counselor at Avenue Investment. “The increase in stock of 1,000 to 10,000 units a month may hold $250,000 in stock yet the revenue will be stuck in receivables. These liquidity crunches are prevented through the linking of inventory growth to the available working capital and credit terms of suppliers.”

Tip: Review your figures, not just your feelings. Taking a hard look at your key business data will help you find the actual underlying issues that are holding you back the most, whether they’re in your marketing, pricing strategy, or operations.

3. Build the right team.

At the heart of operations is people. “If they’re not performing, their role and contribution might be unclear,” says Tapper.

Keeping underperformers for too long can drag down growth. Instead, invest in talent aligned with your values and goals.

Tip: With any new hires you make, follow a checklist that you develop before interviewing begins. That way you have a better chance of making sure every role contributes directly to scalability.

4. Automate and optimize.

“Focus on automating like a pro,” advises Kumar Vaibhav Tanwar, Founder of Clickworthy Digital Marketing. Automation is your best friend when scaling. Tools for inventory, customer relationship management, and order processing will help you cut down on manual errors and free up time.

Muhammad Imran Khan of Brand Ignite highlights platforms like Shopify Plus for their scalability, stating that “improving website performance and user experience ensures that increased traffic can be managed without hiccups.”

Tip: Use platforms that grow with you. Automate repetitive tasks to handle higher volumes without sacrificing quality.

5. Strengthen supplier relationships.

Strong supplier relationships are critical, says Brandon Hartman of BeyWarehouse. “Ensuring that you have a great working and professional relationship with the suppliers you work with means that you can expect consistent high-quality items and timely delivery.”

The opposite is also true: a rocky supply chain can derail growth.

Tip: Treat suppliers like partners. Clear communication and reliability build the trust needed for scaling.

6. Master financial planning.

Andy Gartland of Fitstraps UK stresses the importance of managing overhead costs during growth. “Think new employees, expanded warehousing, and fulfillment costs. Always make double sure that these costs are factored into your scaling plan to avoid unsustainable growth.”

Tip: Track media spend efficiency holistically, not just through platform metrics. Make sure every dollar works toward sustainable revenue growth.

7. Scale marketing effectively.

Before you spend a lot of time and money building systems to scale, you need to have compelling reasons to believe your marketing systems can help you bring in leads. Otherwise, you risk ballooning operating costs and not having the revenues to make up for it.

Tapper highlights the importance of understanding your customer acquisition costs and lifetime value (LTV). “What’s your ratio between LTV and CAC? Understand if you can scale the current ads or need to improve the marketing.”

Tip: Benchmark your CAC against industry standards. Test higher price points or adjust marketing strategies to maximize ROI.

8. Optimize customer experience.

Brian Lim of iHeartRaves points out that “maintaining proper coordination between inventory, order service, and online customer service” is key to managing larger volumes without sacrificing satisfaction.

His logic makes perfect intuitive sense, too. If you win a bunch of new business and you find yourself unable to fill orders, process returns, or answer questions in a timely manner, that new business is not likely to stick around for long.

Tip: Streamline logistics and focus on a seamless customer journey. Use scalable tech to ensure consistency across every touchpoint.

What’s the formula for eCommerce business success?

The formula for success in eCommerce isn’t a one-size-fits-all recipe. Rather, it’s more useful to think of it like a balance of strategies tailored to your brand, customers, and goals.

At its core, success hinges on attracting the right audience, converting them into customers, and nurturing those relationships for the long term.

Combining sustainable channels like SEO and content marketing with high-intent strategies like paid ads and email campaigns will help you create a growth engine that’s both effective in the short run and adaptable in the long run.

Here’s how to build your formula for success.

1. Prioritize high-intent traffic.

“Focus on what brings in real customers, not just traffic,” says Matthew Engelage of Chin Mounts. He highlights the value of search ads, organic SEO, and email marketing. Social media might generate awareness, but higher intent platforms drive conversions. “Retargeting is also a must—remind people why they clicked in the first place.”

Tip: Focus ad spend on platforms where users actively search for products, like Google Ads, and combine it with retargeting campaigns to recapture interest.

2. Leverage the long-term power of SEO.

SEO is often overlooked by eCommerce businesses, but Olivia Tapper calls it the “[backbone traffic]” for sustainable growth. “When your potential customers are searching for your product or service, they find you]” SEO’s ROI grows over time as consistent investments lead to compounding results.

Tip: Conduct keyword research to target what customers are actively searching for. Optimize your site to rank higher, and let SEO reduce reliance on paid traffic.

3. Use content marketing to engage and educate.

“Creating engaging and educational content is a great way to bring in organic traffic,” says Brandon Hartman of BeyWarehouse. “Organic traffic is high-value traffic since these people [are likely searching] with intent to buy.”

Tip: Publish blog posts, tutorials, and product guides that answer customer questions and establish your brand as an authority in your niche.

4. Blend digital channels for sustainable growth.

David Taylor stresses the importance of combining “content your readers will like, SEO to boost your visibility, personalized targeted ads, and automated email campaigns.”

Muhammad Imran Khan echoes this sentiment, suggesting a mix of SEO, content, and paid campaigns, complemented by “retargeting ads and personalized product recommendations.”

Tip: Use SEO for organic visibility, email campaigns for retention, and paid ads for instant results. Layer retargeting ads and product recommendations to boost ROI.

5. Build trust with user-generated content and influencers.